Observing Technology Trends and Product Design Challenges

During this era, two major trends are affecting electronic products. The first one is that products are performing increasingly faster and the second one is that products are becoming increasingly smaller. With these two trends, manufacturers have faced many challenges when designing high-speed, high-frequency, and small-sized products. Especially when designing connectors, it’s extremely difficult to design small-sized and high-frequency connectors because higher frequency leads to more attenuation and interference.

When an engineer has worked hard on software and created a high-frequency connector sample, it’s devastating to find out the connector is not up to standards, failing the verification test. The engineers will start wondering if there was an issue during the simulation, implementation, or measurement phase. Experienced engineers usually have confidence in their simulations and implementations, so they rarely look at the measurement phase. However, there are many crucial points during the measurement phase.

Easy-to-miss Risks of High-frequency Connectors

Allion, a professional testing laboratory with decades of experience, has analyzed and summarized the data that most engineers often ignore. It was found that the PCB board can potentially affect high-frequency connectors.

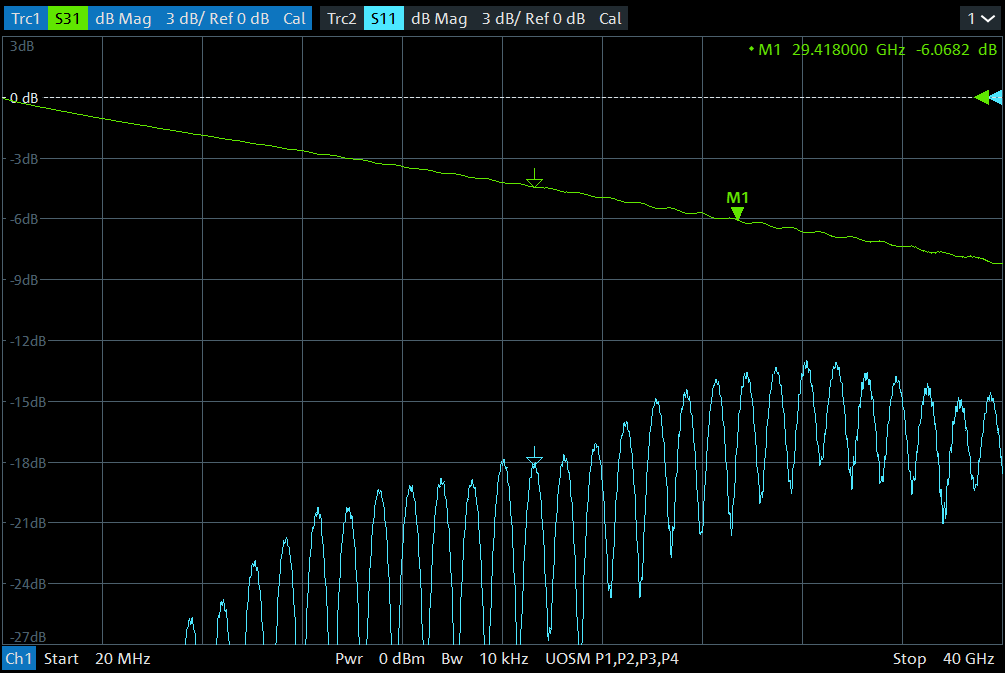

When measuring the frequency of the connector, it must be connected through the PCB board. A PCB board is considered to have a good design when it can be completely de-embedded. However, there is a basic condition that people tend to ignore, which is the intersection of IL and RL for 2xThru. In theory, it’s best if there is no intersection at all.

When making PCB high-frequency fixtures for connectors, we recommend using a special PCB board, instead of using a common one. If you use the wrong PCB board, you will end up wasting a lot of time as making a fixture will take more than 4 weeks. You could also end up wasting money when you find a cheap company that makes boards but they have no experience or professional equipment, resulting in starting the process all over again.

Allion can provide the following to help clients avoid the above-mentioned issues:

- Allion is familiar with the specifications of high-frequency connectors in various industries, and Allion is also an internationally certified laboratory, having partnered with many international associations.

- Allion has decades of testing experience.

- Allion has a complete range of testing equipment to ensure products meet their required specifications.

Faster, Easier, Better: The Most Trusted High-frequency Connector Testing Consultant

Faster

With industry-leading high-frequency and high-speed measuring capabilities, Allion is able to provide a faster and accurate test results and help our clients to further accelerate the product testing cycle.

Easier

Allion has decades of project experience and can provide PCB board design and testing services.

Better

Allion has more than 30 years of professional experience and has many professional technical teams. We can provide educational training and share our experience with our clients so they can better understand the technology.

If you have any further needs for testing, verification, or consulting services, please feel free to contact us through the online form.