Highly Accelerated Life Test (HALT)

Allion is the only test lab in Asia to provide highly accelerated life test (HALT) services with Typhoon 8.0. Exposing your DUT to different levels of stress conditions, the testing time is reduced from months to a few days. HALT tests can expose the weaknesses of your products in a short time, enabling you to find out product defects and flaws within days.

6 reasons to use the HALT Service

- Enacting accelerated tests to discover the defects, flaws, or any potential risks that could be carried on to the later stages of product development

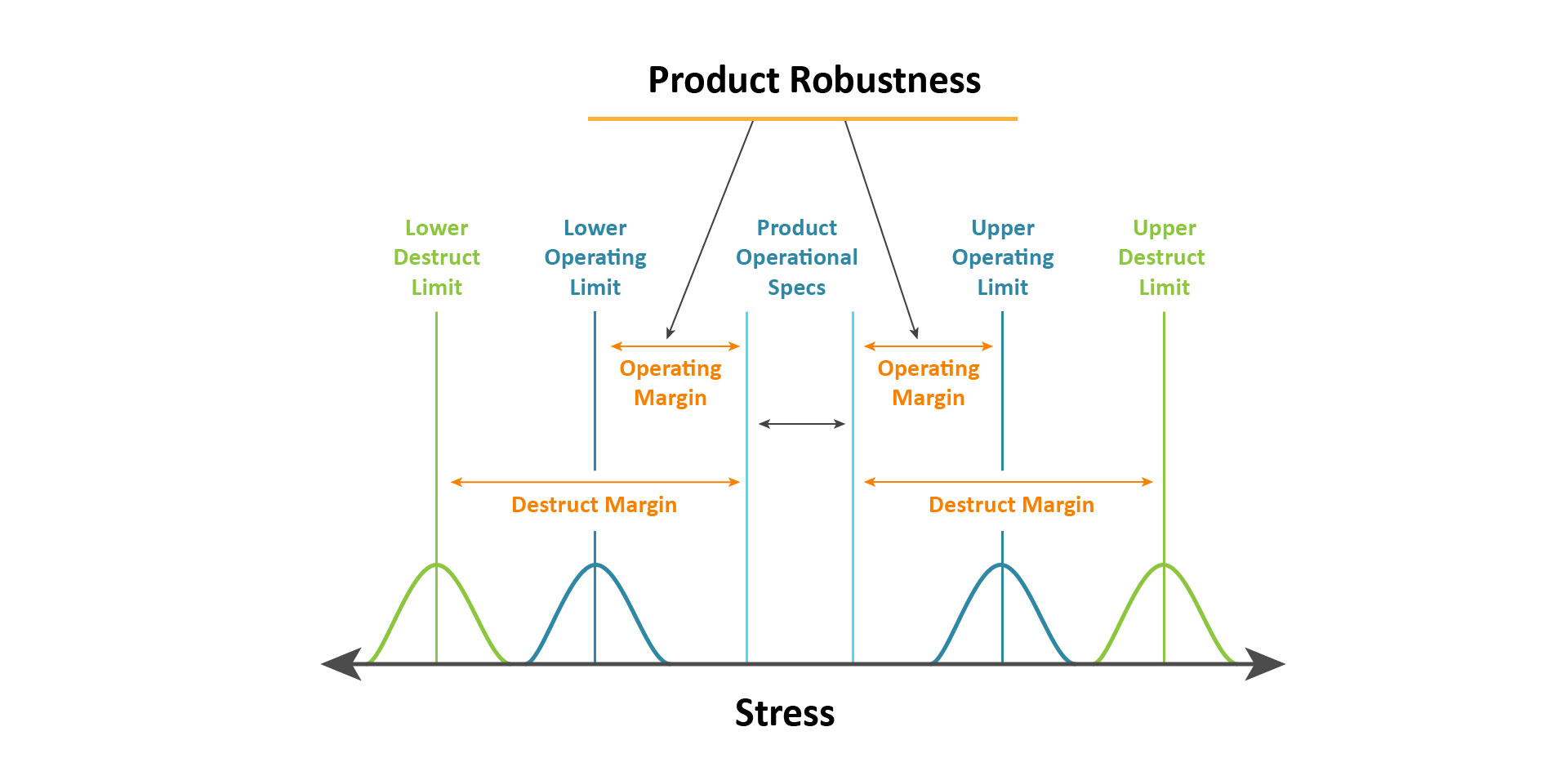

- Pushing products to operation limits with rigorous stress tests, verification, and validations

- Evaluating through testing whether the product design meets the product life cycle and warranty period required by customers

- Increasing the reliability of your products through testing, lessening the likelihood of facing recalls and warranty claims after product launch

- Complete the product cycle in a shorter time and shorten the time to market

- Avoid defects in the early stages of the product developmental process, satisfying clients’ needs

Allion provides a one-stop comprehensive HALT service. With a DUT sample you provide, Allion will discover the product’s potential defects, including issues with components, materials, mechanisms, process design, and more. We aim to help you improve product quality.

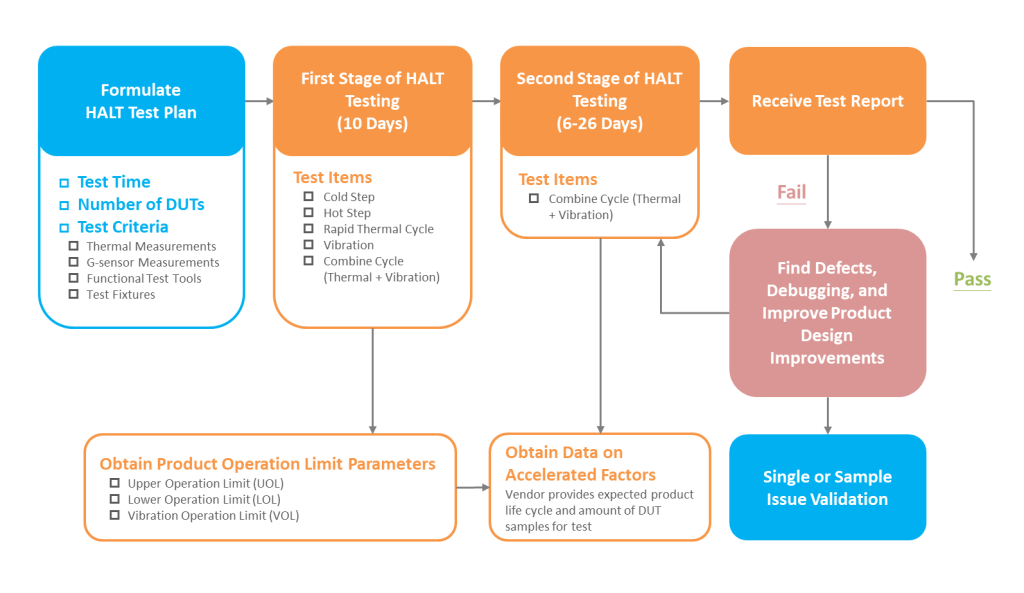

HALT Procedure

1st Phase: Locate Potential Risks

HALT Test Cases

- High-temperature step stress

- Low-temperature step stress

- Rapid thermal transitions stress

- Vibration step stress

- Combined Environment stress

4 Steps of the HALT Test

- Precipitation

Discover defects and flaws - Detection

Observe for any anomalies - Failure Analysis

Determine the root cause of failure - Corrective Action

Modify the design or process to prevent the same failure

2nd Phase: Combined Tests to Determine Appropriate Warranty Period

Combine Cycle (Thermal + Vibration)

In the 2nd phase, the DUT undergoes the combined test, involving rapid thermal and vibration cycles. Through physical and chemical calculations, we can estimate the lifespan of the product after enduring long-term stresses.

Not only can Allion help you identify potential defects in product design and production process, but we can also calculate whether the product can achieve the expected performance based on the existing design and materials, thereby reducing repair and recall costs due to potential risks.

Discover weaknesses to boost product quality

Developers are often annoyed with the following scenarios:

- You are about to launch your product, and you have no time left to conduct 6 or 12 months of reliability tests.

- You have listed all the potential risks and issues, but you have no means to be sure about the possible consequences.

- Your product is being recalled, losing clients’ trust.

In fact, the purpose of enacting HALT tests is to find the weaknesses of your products when they are only prototypes. With rigorous stress tests such as vibration, high/low temperature step stress, and rapid thermal transitions stress test, you can discover the weaknesses soon enough so you do not face costly suspension of product development or recall of products later.

Faster but better

Ideally, we want to find out all the defects and flaws in the early stages of product development, prototype, EVT, DVT stages, but there is usually not enough time to conduct all validation and verification tests.

HALT is designed to shorten the testing time. This test accelerates the product life cycle, so developers can comprehensively learn the defects and flaws of their products. By exposing the defects, we can focus on the critical issues and modify the products.

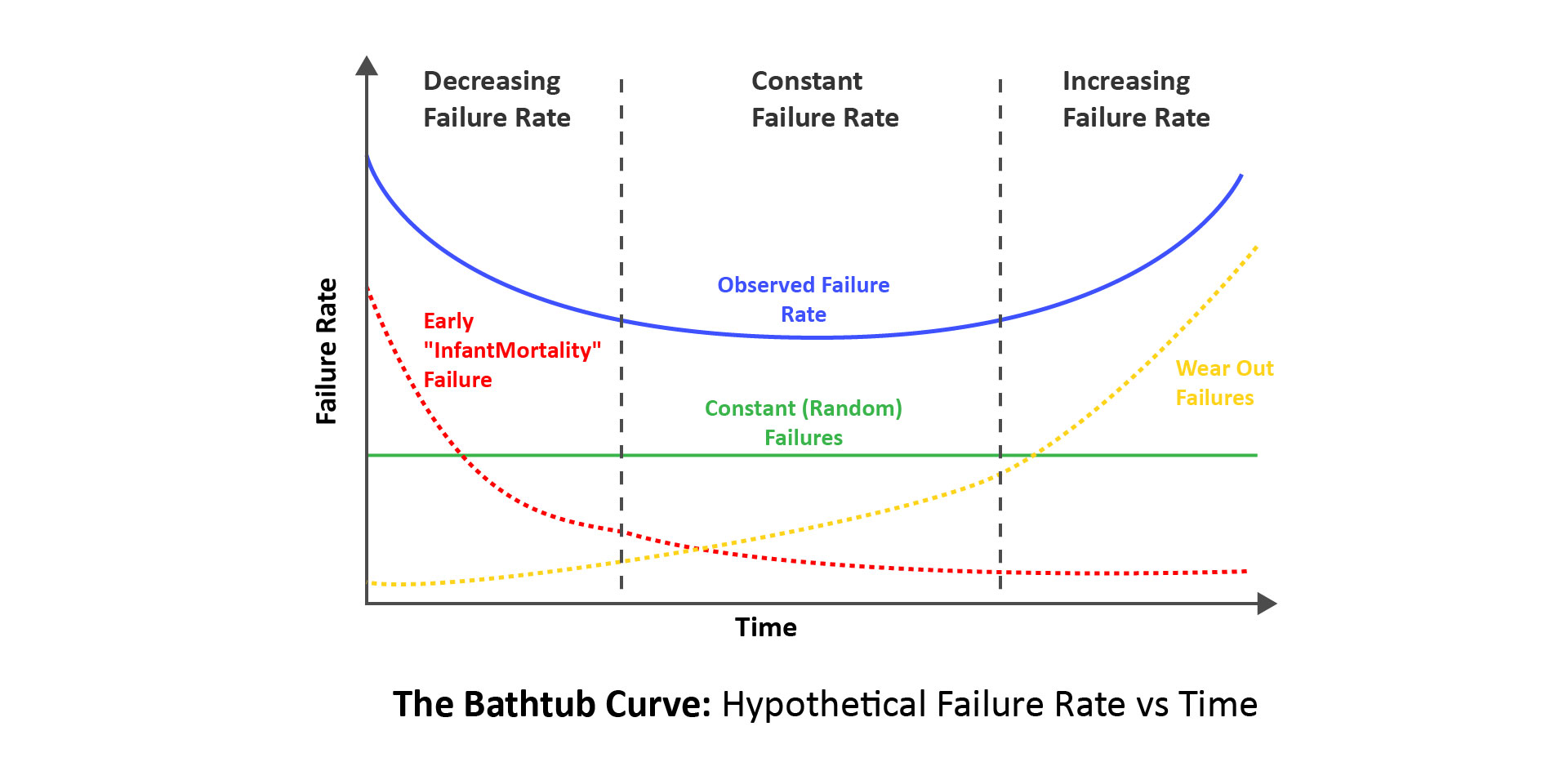

The bathtub curve depicts the observed failure rate, constant failures, infant mortality rate, and wear-out failures.

For more information on the HALT test, please feel free to email us or fill out the HALT contact form.