Hardware in the Loop (HIL) Solution

The Allion Hardware in the loop (HIL) Solution can save vendors from having to build a real-world test environment and quicken the software and hardware development time frame. It can help ensure the functionality of the dashboard, system, and algorithm as well as meet the validation demands of factory-installed products and aftermarket products.

According to OICA statistics, global car sales reached 82.68 million vehicles in 2021, while projections show considerable growth in demand in 2030. This indicates the car is a major means of transportation worldwide, and requirements for vehicle safety will increase accordingly.

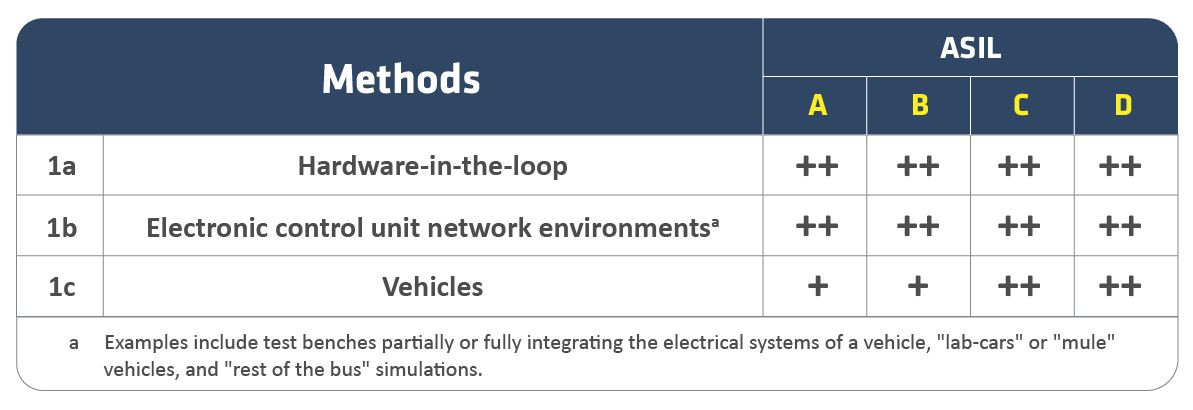

ISO 26262 has 4 different ASILs—ASIL A, ASIL B, ASIL C, and ASIL D. ASIL A is the lowest level of safety while ASIL D is the highest level.

ISO 26262 Part 6, which concerns product development at the software level, further illustrates the validation and verification required for the different safety levels, confirming product functionality meets safety requirements.

What is Hardware in the Loop (HIL)?

Conforming to ISO 26262 requirements, Allion HIL testing is an integrated automation test method that avoids manual errors through automation. Allion HIL testing is a great way to simulate testing for functional safety requirements for components, ECU, and automotive Ethernet.

Manual Testing Causes Inconsistencies

.

.

HIL Testing—Accurate, Efficient Simulation Testing

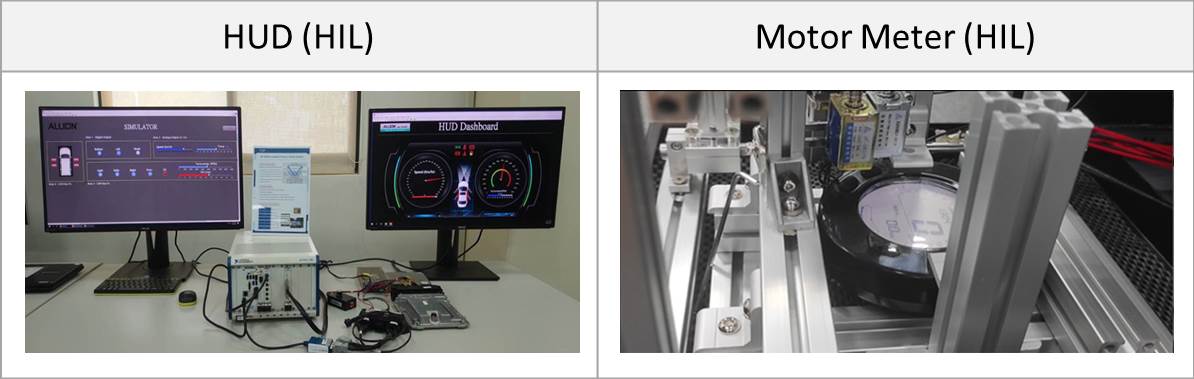

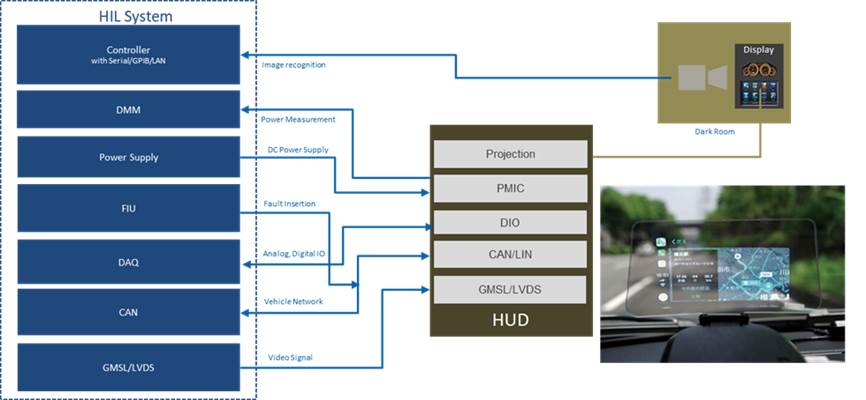

HIL testing can be divided into 2 categories—HUD (HIL) for Cars and Motor Meter (HIL) for Motorcycles. We prevent the need to build a real-world test environment and quicken the software and hardware development time frame. It can help ensure the functionality of the dashboard, system, and algorithm as well as meet the validation demands of factory-installed products and aftermarket products.

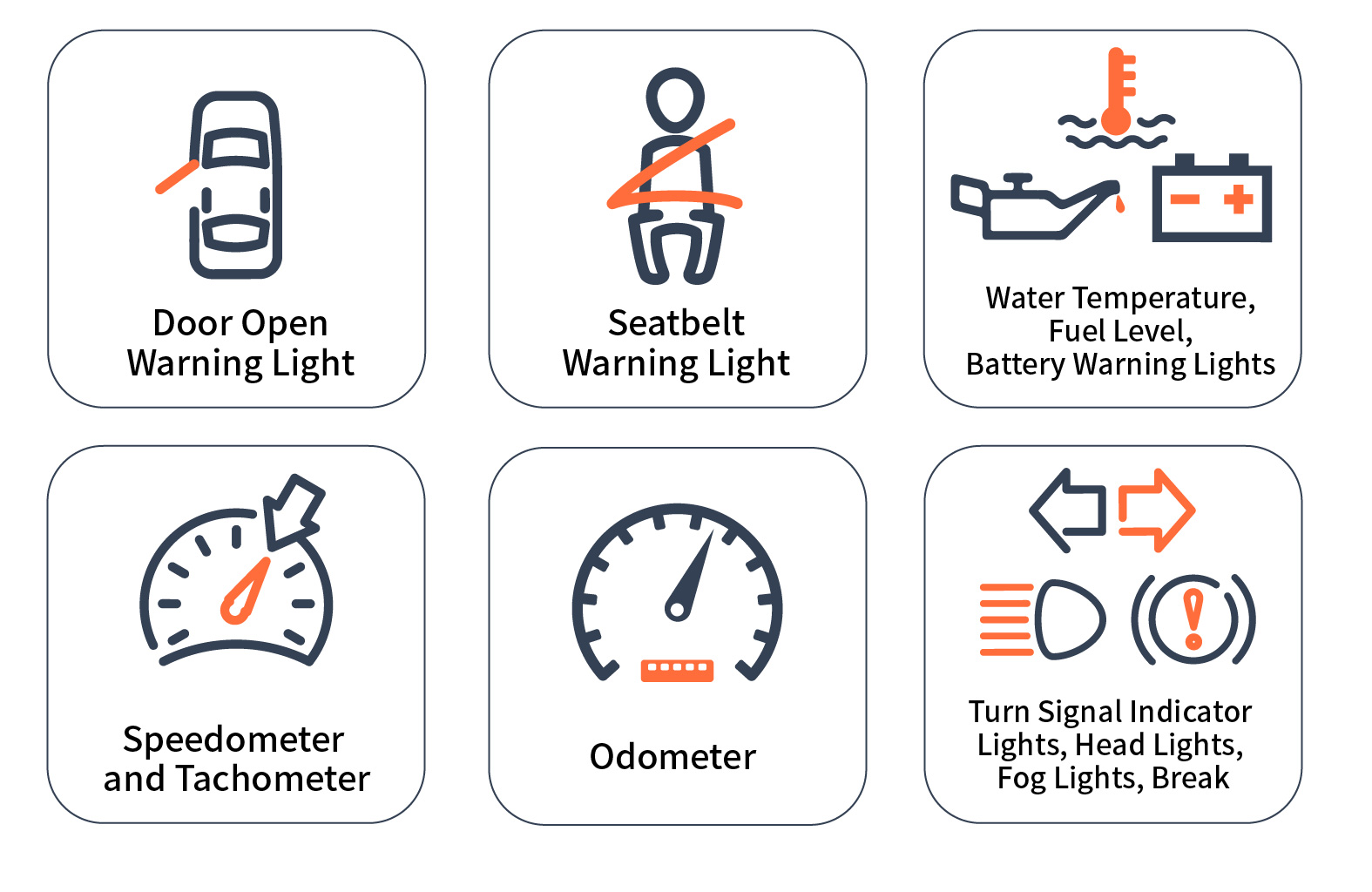

Dashboard Simulation Tests for Various Functions

For the car dashboard, we provide signal simulation testing for digital output, analog output, CAN bus transmission, and other dashboard functions to recreate signals during various scenarios on the road.

We utilize a variety of scenarios to validate different control units and confirm the safety of a DUT in terms of functional testing and complex scenario design tests.

HIL Simulation Test Structure

If you have HIL Simulation Testing or head unit consulting needs, please contact us at service@allion.com or fill out a contact form.