Development and Charging Applications of USB Technology

The USB technology, from the USB 1.0 version to the USB 4.0, has undoubtedly made a significant impact on our daily lives. The evolution of USB technology is not only reflected in the increase in transmission speed but also in the increase in charging power delivery. From the initial maximum power supply of only 500 mA to the current USB Power Delivery (PD) specification, it enables power output of up to 240W. This allows USB charging quickly to charge mobile devices and meet the charging needs of high-power devices such as laptops.

In the application of charging, with the popularity of smartphones, tablets, and other portable devices, USB charging has gradually become one of the main power supply methods for these devices. It is currently widely used in daily scenarios. For example, we use USB chargers to charge smartphones, tablets, and Bluetooth headphones at home. Various USB charging sockets are available at offices, schools and other public places. In addition, USB charging is widely used in transportation, such as cars and airplanes. However, with the popularity of USB charging, corresponding risks have also gradually emerged. One of the main risks is the quality issues of charging cables or chargers, such as overheating, overcharging, or short circuits, leading to device damage or even fires.

USB Charging Cable Overheats and Melts?

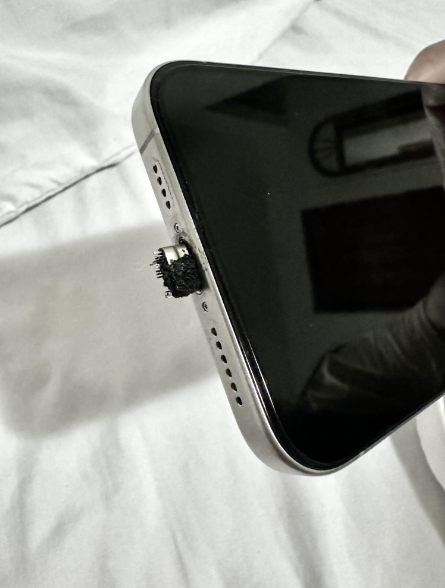

With the popularity of USB charging products, many manufacturers have recently recalled their USB charging products due to quality issues. One recent news report stated, “Tragedy! iPhone 15 Pro Max’s Type-C Charging Cable Overheats and Melts.” The news pointed out that a netizen posted on a forum stating that after using the iPhone 15 Pro Max for about a month, the entire phone heated up during a night of charging, causing burns to his fingers and obvious scorch marks on the phone. When he tried to remove the charging cable, he found that the plastic part had melted due to the high temperature, and the USB Type-C metal connector was stuck in the phone’s port.

The Type-C metal connector melted due to the high temperature of the charging cable and got stuck in the phone jack

(Source: GIZMOCHINA)

Many netizens believe that the main reason is the use of inferior charging cables and chargers, so they recommend using the original charging cables instead of buying cheap but poor-quality ones. However, with the rise of environmental awareness, companies like Apple no longer include charging cables or chargers, and more phone manufacturers are following suit. Therefore, choosing a suitable charging cable and charger has become a challenge.

Procuring USB Charging Cables, Remember DC-Load and T-Rise Verification Before Shipment

In fact, brands or companies can ensure the quality of the charging cables on shelves at a low cost. Allion recommends that products undergo the following two verifications before shipment so that a company can effectively ensure the quality of the charging cables.

- DC-Load: DC load is used to simulate the condition of 3C products under long-term charging to test whether the cable will be damaged due to time or temperature, causing the cable to fail to supply power normally.

- T-Rise: T-Rise is used to test how much the temperature rises under high-load usage in an environment. Its purposes are as follows:

- Users may be burned when they touch the device due to overheating after prolonged charging.

- Ensure that products will not cause too much loss or burning due to high temperature during the power transmission.

Through the following instruments, companies can perform the verification items above:

Allion is an Authorized Independent Test Lab by USB-IF, and has accumulated over 30 years of project experience. The Allion team can assist manufacturers in getting certification for USB-related products quickly, and provide the best consulting services. Additionally, we can assist brands or manufacturers in developing technical specifications, quality specification requirements, and pre-shipment acceptable quality level standards in procurement or tender documents, allowing companies to procure products with quality assurance.

Faster, Easier, Better! USB Product Consulting Services

Faster

With professional testing techniques and rich experience, we can provide you with fast and accurate evaluations to shorten the design verification time. Allion has a wide range of instruments and highly accurate test environments to meet the verification needs of all USB products. Instruments include:

- Electrical measuring instruments: oscilloscopes and network analyzers.

- Mechanical-related instruments: durability testers, push pull testers, automatic swing machines, and bending testers.

- Reliability-related equipment: temperature chambers, ovens, gas corrosion testers, and vibration testers.

Easier

In addition to certification services, Allion provides customized consulting services. When problems occur, we can quickly analyze the issues and find the causes based on our accumulated experience, advanced equipment, and reliable environment.

Better

Allion can provide suggestions for solving problems that occur, allowing customers to correct problems in the shortest time, improve product quality, and quickly enter the market to seize market share.

More from Allion

If you have further requirements for cables, connectors, or procurement-related consulting services, please feel free to contact us.