With the rapid advancement of technology, the ubiquity and necessity of digital learning are undeniable. Students of the digital learning era are no longer passive recipients of knowledge but active participants in their education. Consequently, tablet devices play an indispensable role in the wave of digital education. Through interactive teaching software, students can better grasp abstract concepts, while educators can adjust teaching content more flexibly, providing personalized learning experiences. As a result, educational institutions worldwide have been procuring tablets in large quantities, aiming to elevate the overall quality of digital education.

Why Quality Validation is Crucial: Analyzing the “One Student, One Tablet” Procurement Case in Tokushima, Japan

However, before governments embark on extensive tablet procurement, have they considered the functional specifications and quality requirements? Have they clearly outlined and set acceptance criteria in the tender documents? Furthermore, do government procurement personnel have sufficient and in-depth understanding of tablet-related technical specifications? Do they possess adequate professional knowledge for quality confirmation methods? These are significant issues that governments face when procuring tablets in large quantities, and a recent real-life case unfolded in Japan.

In an effort to promote one tablet per student, the Tokushima Prefectural Board of Education purchased 16,500 tablets from a Chinese brand for 28 schools (including high schools) in the prefecture in 2020. Unexpectedly, by 2021, 694 tablets had malfunctioned. By 2022, the number rose to 627, and by September 2023, the staggering figure reached 2,859 malfunctioning tablets. This not only forced students to share tablets, negatively impacting teaching quality. Eventually, the Tokushima Prefectural Board of Education Superintendent had to hold a press conference to publicly apologize for the procurement controversy.

According to statistics reported by NHK, the failure rate of the procured tablets has reached an exaggerated 17.3%, which may continue to increase. This incident undoubtedly serves as a classic case where tablet quality was not effectively verified before shipment. Even if government procurement personnel were to establish quality requirements and commission inspection agencies to confirm acceptance criteria, there is no guarantee of effective implementation and enforcement.

How should acceptance criteria for procurement be regulated?

Allion has been providing quality verification consultancy services for over 30 years, with extensive project experience in technical specifications and quality requirements for various electronic products. When procuring electronic products, Allion can assist governments or enterprises in formulating technical specification standards, quality specification requirements, and pre-shipment acceptance criteria in procurement or tender documents.

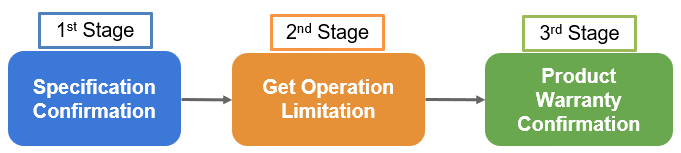

Taking the tablet procurement case in Tokushima Prefecture, Japan as an example, Allion suggests three stages of acceptance criteria verification:

Stage 1: Confirming product operating temperature and vibration against declared specifications.

Extract ten sample units and conduct a comprehensive cyclic test based on declared operating temperature and vibration ranges. Use ten cycles as the acceptance criterion to ensure that all ten tablets operate normally under these ten cycles of low to high temperature and from no vibration to maximum vibration.

The acceptance condition at this stage must be set to a “100% pass rate” to confirm that the declared specifications are consistent with the actual product usage

Stage 2: Ensuring the product’s operational limits.

In the second stage, Allion suggests using five tablets to determine the three extreme values of product operation: maximum temperature, minimum temperature, and maximum vibration value. After identifying these three extreme values, compare them with the product’s declared specifications. For typical electronic products, the operating limit values should exceed the declared specifications by at least 10% (which can be set as the acceptance criterion at this stage) to effectively reduce the product failure rate.

Stage 3: Confirming the product warranty period matches the declaration.

Traditional product life tests typically take thousands of hours and require a large number of samples, consuming a significant amount of time and cost. However, Allion has a rapid verification solution for product warranty periods, which can confirm whether the product meets the claimed warranty period in a short time.

For example, in the case of tablets, assuming we test ten tablets for eight days under conditions of “operating extreme values of -30°C to +70°C and vibration limit of 50Grms,” we can verify a warranty period of up to three years. The acceptance criterion at this stage is that the verified warranty period matches the declared warranty period.

Through these three stages of acceptance criteria verification, Allion is confident that it can assist customers in confirming the quality of shipped products in less than three weeks, significantly reducing the probability of failures and repairs after use.

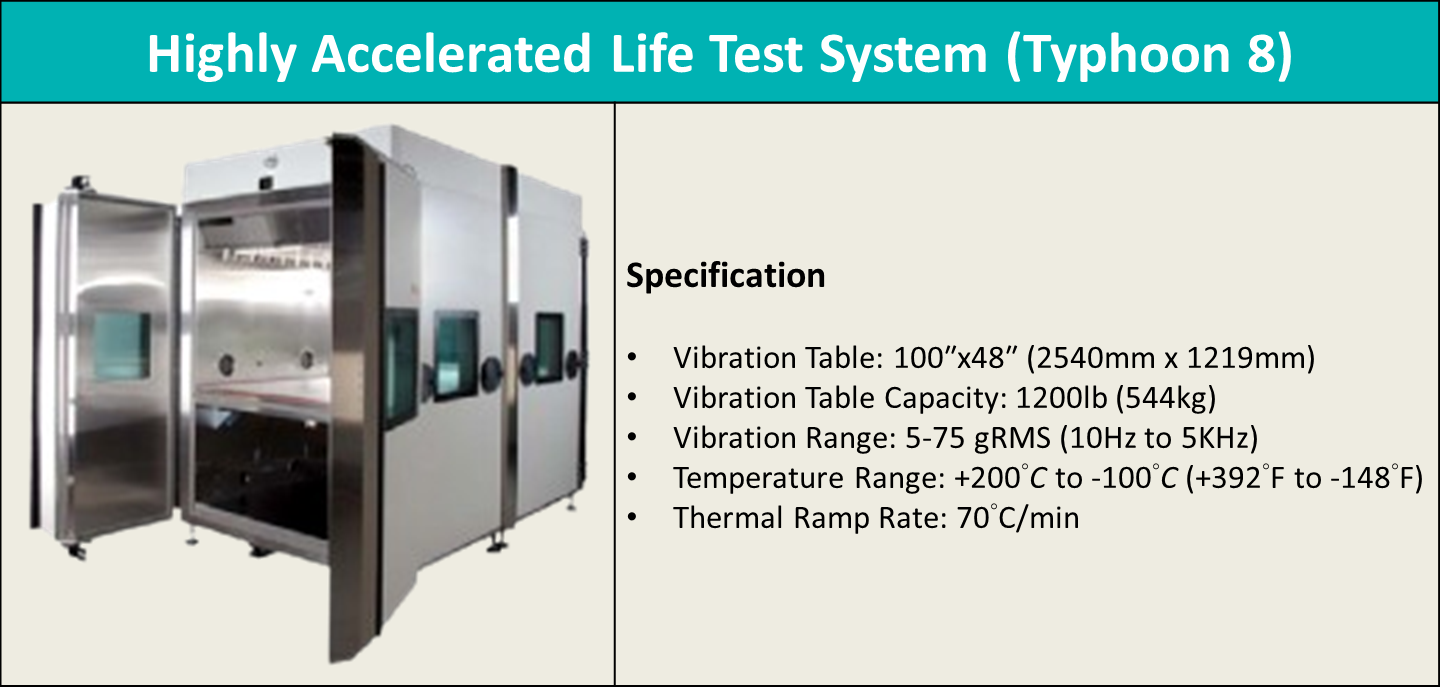

HALT (Highly Accelerated Life Test): Identifying potential product defects in a short time

In addition to extensive verification experience and technical capabilities, Allion has a comprehensive testing environment and equipment to assist customers in product quality verification and consultancy services. We have two HALT machines of different specifications, capable of accommodating products of various sizes for quality verification, ranging from small components to 65-inch screens or televisions. The maximum platform load capacity of the test machine can support up to 500 kilograms, covering almost all types of electronic products.

Faster, Easier, Better! Procurement Consultancy Services by Allion Labs

As a professional testing and consultancy laboratory, Allion can plan customized testing solutions based on different product stages and verification needs, providing customers with faster, easier, and better one-stop technical consultancy services.

Faster

Leading industry capabilities in high-frequency and high-speed measurements allow Allion to accelerate product testing cycles for various standards or specific specifications, regardless of the product stage.

Easier

By incorporating AI and automation solutions, Allion ensures that every test is “qualitative, quantitative, and reproducible,” helping customers enhance product performance in a more convenient manner.

Better

With over 30 years of professional experience, a dedicated technical team, and a complete testing environment and equipment, Allion is committed to providing customers with better service quality based on rich user scenario testing experience.

If you have further needs for consultancy services related to technical specification standards, quality specification requirements, and pre-shipment acceptance criteria in procurement or tender documents, please feel free to explore the following services online or contact us through the online form.