The Touch Wave: Applications and Developing Challenges of Stylus

The rapid advancements in touch and display technologies have driven the proliferation of touch screen devices, fundamentally changing people’s habits in note-taking and drawing. Paired with these devices, styluses, and digital pens have become popular electronic products. In addition to taking daily handwritten notes and signatures on computers or tablets, creators use them to engage in creative activities such as painting, illustration, and interior design, covering the fields of art and design. Stylus pens eliminate the need to discard entire works due to mistakes, so you do not have to worry about material wastage. Additionally, creators can readily modify and store sources of inspiration through the use of digital tools. Styluses bring convenience to our lives and workspaces. However, in stylus design, manufacturers often prioritize precision while overlooking potential usage risks in real-world scenarios. Allion shares insights into key considerations developers should address to mitigate these risks.

What are The Hidden Risks of Stylus Pens? Contextual Cases, Potential Risks, and Solutions

Let’s talk about common scenarios of stylus pen drops. Imagine during a phone conference with a client, you absentmindedly place your stylus temporarily on your tablet’s touchscreen, preparing to jot down the client’s requirements. Suddenly, with an unintentional flick of your hand, the stylus accidentally falls off the edge of the table to the floor. Similarly, a child painting on a tablet with a stylus may experience unstable hand grip, causing the stylus to slip out of their hand and onto the ground. In other instances, a student might place the stylus on an unstable desk and inadvertently knock it off while getting up, as their foot collides with the desk. In such cases, the stylus may lose its precision and sensitivity after multiple drops.

Customized Testing Solutions for Stylus Pens

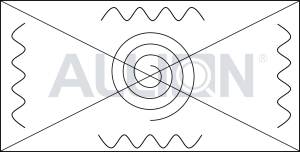

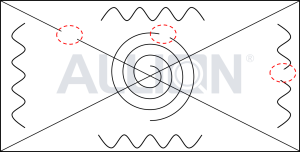

Due to the occurrence of the situations above, Allion collaborates with major manufacturers to develop validating methods for stylus pens subjected to multiple drops and various angles, as illustrated in the diagram below:

- Continuous drawing of diagonal lines.

- Continuous drawing of circles to detect any discontinuities in the shapes.

- Random drawing of wave patterns to identify any discontinuities.

Stylus pens are mostly designed in a pen-like form, allowing users to hold the pen body for operation. When the pen tip touches the touchscreen, it communicates with the touchscreen through sensing components, sensing technology, and communication technology to achieve writing and drawing effects. Although the stylus pen’s shape is suitable for users’ hand grip, making them comfortable for long-term use, unstable grip or insufficient desktop space can cause the pen to slip from the hand or roll off the edge of the desk. This may damage the pen tip and casing, or even internal sensor component damage, rendering it unusable. Allion’s extensive experience in user scenario testing and verification services can help you mitigate potential risks.

Faster, Easier, Better!Allion User Reliability Testing and Verification Solutions

With the diversification of product applications, traditional reliability testing standards have become inadequate to meet today’s demands. We recognize the critical role that user scenarios play in uncovering potential risks. Leveraging our rich experience in user scenario testing, Allion provides clients with professional and thorough user reliability testing and verification services.

Faster

Drop Test Machine

Drop Test Machine

- Model: VS-1018-160

- Maximum Load Capacity: 65kg

- Testing Height: 30-160cm

- Base Material: Stainless Steel

Learn more: Accessory validation services

Easier

Allion first evaluates the user scenarios of the product, considering in advance the different angles at which the product may fall. We can provide fixtures to address angle issues during testing and assist customers with data integration, initial analysis, and problem clarification after testing. This helps make the product more competitive in the market.

Better

Allion boasts a professional testing team with extensive testing experience. Common types of drop tests include products themselves, cables, connectors, and even product packaging. We can tailor test content according to customer needs, providing customers with a more comprehensive service quality.