With the continuous advancement of USB charging technology, the charging power has evolved from early 2.5W (USB 2.0), 4.5W (USB 3.0) to the current 240W (Type-C). However, while the appearance of commercially available Type-C cables may be similar, the charging efficiency varies greatly. When used with fast-charging compatible chargers, the power output may not reach its maximum, resulting in slow charging. Therefore, it is not only the responsibility of cable manufacturers to impose quality control requirements on fast-charging cables, but also important for manufacturers shipping products with fast-charging cables to pay attention to the quality requirements when purchasing compatible cables.

Fast Charging USB Type-C Still has Potential Risks.

There are various USB Type-C cables on the market claiming to support “fast charging,” with prices ranging from tens to thousands of dollars. While fast charging technology provides users with a faster and more convenient charging experience, there are also some potential risks involved. Poor-quality fast charging cables may not achieve the optimal performance of fast charging technology. The impedance and materials of the charging cable affect the efficiency of charging, which may result in longer charging times or slower speeds, contradicting the original intention of using fast charging. Additionally, fast charging technology typically involves higher current delivery, which may lead to excessive heat generation in chargers, charging cables, and devices themselves. Prolonged exposure to high temperatures can damage the battery and device health, and even pose some safety hazards.

Let’s learn together about the key points to consider when purchasing fast charging cables.

Allion has various environmental equipment and know-how to assist manufacturers in verifying conductor materials.

As a USB-IF authorized testing laboratory, Allion has long-term partnerships with cable suppliers. We understand deeply that the materials of USB Type-C cables can affect the efficiency of charging and data transmission. There are several factors that procurement parties should pay attention to:

▶ Conductor material: The choice of conductor material directly affects the efficiency of current transmission.

High-quality conductor materials, such as high-purity copper wire, have superior conductivity, reducing energy loss during current transmission. This helps improve charging efficiency and reduces heating.

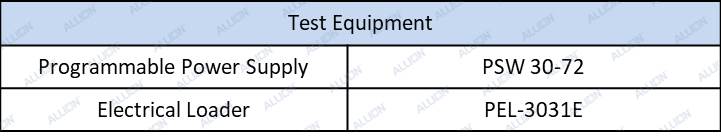

☉ Allion’s equipment and know-how.

▶ Insulation material: The quality of insulation material affects signal penetration and protection.

Good insulation material can effectively prevent electrical short circuits while helping to maintain signal stability. On the other hand, low-quality insulation material may cause signal attenuation, reduce charging efficiency, and even lead to safety issues.

☉ Allion’s equipment and know-how.

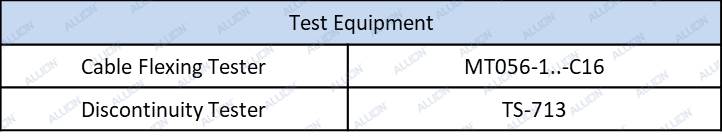

▶ Outer material: The flexibility and abrasion resistance of the outer material can affect the flexibility and durability of the cable.

A flexible outer material makes the cable easier to bend, enhancing usability, while abrasion resistance ensures that the cable is less likely to be damaged during long-term use. Although this does not directly affect charging efficiency, it does impact the overall performance of the cable.

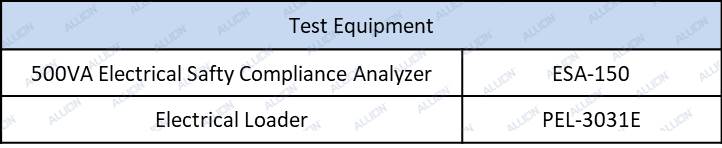

☉ Allion’s equipment and know-how.

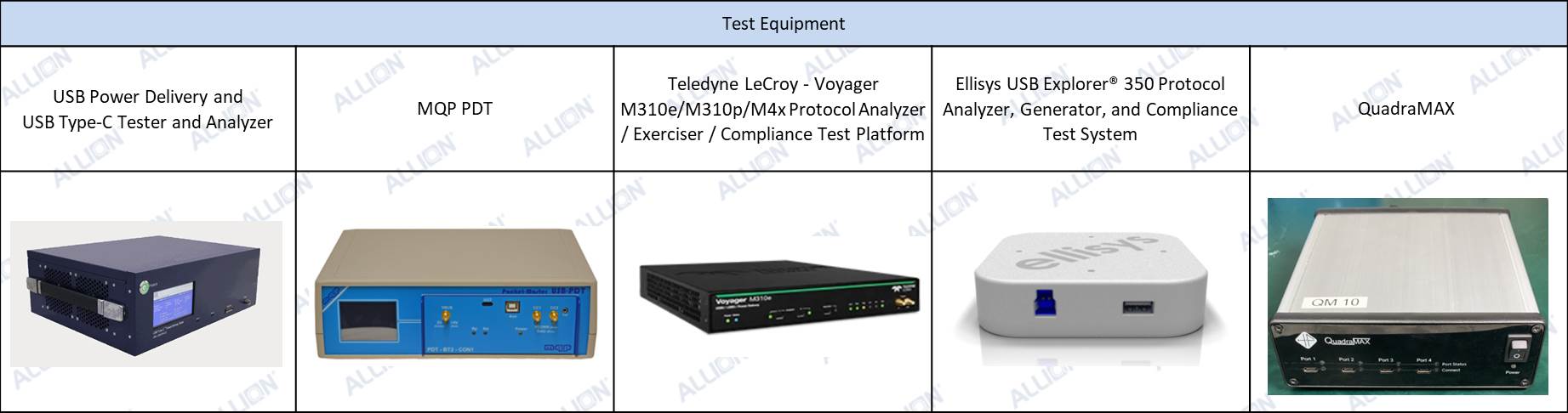

Use cables with E-Marker chips: The “E-Marker” chip is an identification IC embedded in USB Type-C cables, responsible for information negotiation between the charging cable and the device. It declares the cable’s capabilities and manufacturer information. Cables with E-Marker chips can provide different currents based on their chip type, ensuring safe charging.

Allion’s equipment and know-how.

Allion is a certified laboratory by the USB Implementers Forum. Among the various factors mentioned above, Allion not only provides specification recommendations but also possesses comprehensive equipment environments to offer the most comprehensive testing.

Faster, Easier, Better!Cable Consulting Service

As a professional testing and consulting laboratory, Allion not only designs corresponding testing fixtures but also customizes test plans based on cable products with years of industry experience, providing optimal consulting services. Additionally, we can assist clients in providing quality requirement consulting services when purchasing cables, helping them mitigate most potential issues and reducing the risk of delisting and returns.

Faster

Allion has extensive testing experience with various interface transmission cables and connectors. After clients submit their products for testing, we can promptly provide test results, enabling them to become pioneers in the market with their products.

Easier

Allion has extensive and comprehensive testing experience. Upon receiving a testing request, we conduct a feasibility assessment at the earliest opportunity and provide appropriate test item recommendations along with corresponding solutions to precisely address product issues.

Better

Allion provides end-to-end testing services for customers, integrating and analyzing various test data to optimize products. We also offer customized testing and non-certification testing, providing a wide range of improvement and testing suggestions to reduce the time-consuming issues in product development.

If you have any testing, verification needs, please feel free to browse the following services or contact us through the online form.

Inquiry Form