Getting a “shock” with just a touch?

When it comes to static electricity, it’s a phenomenon familiar to many. Static electricity is common in our daily lives, typically generated due to friction between objects. For example, when we take off clothes made of synthetic fibers, the friction between the fabric and the skin may lead to the accumulation of electric charges. Similarly, walking on a dry carpet can cause friction between shoe soles and the ground, also leading to static electricity generation. It’s important to note that when the body carries static electric charges, touching electronic products may lead to charge transfer, potentially causing damage to the equipment. Electronic products usually contain sensitive electronic components, which are highly susceptible to static electricity. Even though static discharge may exist in forms so faint that they’re invisible to the naked eye, they’re sufficient to cause failures or damage to electronic components.

Example of the effect of static electricity on a child’s hair. (Source: Wikipedia)

ESD (Electrostatic Discharge) testing is a critical testing procedure aimed at safeguarding electronic devices from damage caused by electricity discharge during actual operation. Such tests typically simulate various static electricity discharge scenarios that may occur in real-world usage environments to assess the response and resilience of electronic devices to these events.

During the design phase, engineers typically incorporate anti-static protection measures to reduce the risk of electronic components being affected by static electricity. However, ESD testing remains a necessary step to ensure the effectiveness of these preventive measures in actual applications, helping to enhance the reliability and lifespan of electronic devices while ensuring they operate normally under various environmental conditions. When designed anti-static protection measures are flawed, potential risks may include:

- Damage to electronic components: ESD may cause damage or destruction to electronic components such as chips, resistors, capacitors, etc., leading to equipment malfunction or performance degradation.

- Faults and failures: ESD may result in equipment malfunctions or failures, such as system crashes, freezes, or inability to operate normally, leading to production delays, service interruptions, and potentially customer complaints in the worst-case scenario.

- Data loss: ESD may result in data loss or damage stored in the device, leading to significant impacts on business operations or personal use.

- Cost implications: ESD may increase the cost of equipment repair or replacement.

Test Case

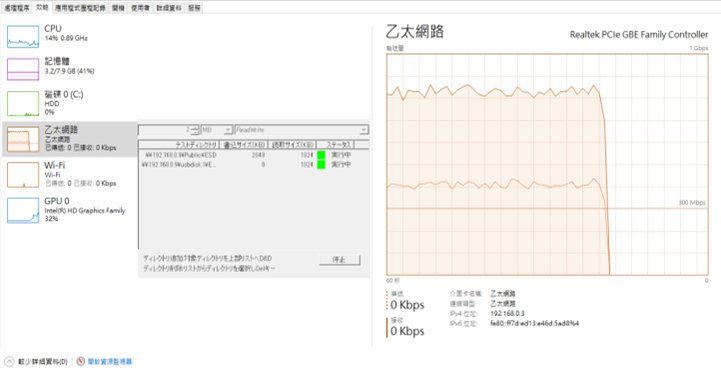

Allion has collaborated with various well-known companies, one of which involved testing a Network Attached Storage (NAS). ESD testing was conducted under continuous packet transmission conditions, and during the testing process, the transmission failed due to the impact of electrostatic discharge. Although recovery occurred subsequently, such situations could lead to delays or data loss.

ESD Solution

ESD testing is an essential test applicable to various electronic products and components such as mobile phones, tablets, laptops, and automotive electronic products. Allion has extensive experience in ESD testing and can provide comprehensive ESD testing services. Experts can assist in understanding whether the product’s ESD protection is adequate, identifying and troubleshooting issues early to minimize customer complaints or brand image loss caused by product failures or malfunctions. Allion’s ESD testing facilities and ESD simulator EDS 30V comply with international static discharge standards IEC 61000-4-2 and automotive specifications ISO 10605, offering customized testing solutions and consulting services according to specific testing needs for IEC 61000-4-2 and ISO 10605, and providing detailed test reports and data analysis to help clients better understand product performance and issues.

Faster, Easier, Better! ESD Testing Consulting Services

As a leading brand in testing and consulting services, Allion has accumulated over 30 years of testing and certification experience. In addition to the mentioned facilities and simulators, Allion has other advantages in ESD testing:

Faster

Leading industry testing capabilities and an excellent assessment team can effectively shorten the testing cycle, assisting in quickly identifying problems and reducing time costs.

Easier

Professional technical consulting teams can provide comprehensive support and testing, ensuring that manufacturers can complete testing easily, allowing you to focus on product development and improvement without spending too much time and energy on testing.

Better

When problems are discovered, engineering experts can conduct problem analysis and provide debugging support services, enabling manufacturers to troubleshoot issues and pass tests in the shortest time possible.

If you have further needs for ESD testing-related consulting services, please feel free to contact us.