The new USB Type-C standard provides tremendous business opportunities for cable and connector manufacturers. In order to achieve maximum benefit from these opportunities, and enhance competitiveness, these manufacturers are constantly trying to find ways to speed up product certification.

Allion Labs, a market leading testing laboratory, successfully held two seminars on May 6 and May 7, 2015 for more than two hundred (200+) attendees. These two seminars not only helped attendees quickly understand the latest USB Type-C specifications, but also accurately prepared them for market changes by reviewing a list of certification action items. Additionally, Allion shared Type-C certification testing FAQs and delivered on-demand Q&A debugging services.

two seminars on May 6 and May 7, 2015 for more than two hundred (200+) attendees. These two seminars not only helped attendees quickly understand the latest USB Type-C specifications, but also accurately prepared them for market changes by reviewing a list of certification action items. Additionally, Allion shared Type-C certification testing FAQs and delivered on-demand Q&A debugging services.

To meet the rapidly rising market demand for USB Type-C certification requirements, Allion has prepared this article for its customers who could not attend and any other interested parties. This article provides an overview of the topics presented at our USB Type-C seminars. It also presents results of the seminar survey which was used to analyze current sentiments. This survey data can provide vendors with deeper insights into potential avenues of growth and obstacles to overcome. As USB technology continues to advance, Allion will continue to provide its valued customers with superior certification services and customized engineering solutions.

Massive Business Opportunities for USB Type-C Market

Recalling the history of USB development, the USB interface has become one of the most successful and omnipresent connectivity solutions in IT devices. These days, not just computers, but, most electronic devices and peripherals come equipped with USB, so that it now occupies a seemingly unassailable position of market dominance.

Now and looking into the immediate future, the new USB Type-C port is ready to support much faster data speeds than previous iterations of USB technology. It also provides enhanced scalability and a slimmer profile that enables thinner and lighter industrial designs. The introduction of the USB Type-C specification is a watershed moment for the cable and connector industry with leading manufacturers competing to snare the greatest market share. The Nokia N1 will be among the first wave of devices with a USB Type-C connector. The bottom of the device has a Type-C port, attached with a 2.0 C to A power charging cable that can be charged at up to 2 amps. The power adapter can also serve as a reliable power source to quickly charge smartphones, tablets, and other mobile devices. In addition, Apple opens up new business opportunities for Type-C peripheral makers with just a single port available on its new MacBook, which takes care of power, data transfer, and display output. China’s LeTV is also launching three new Android 5.0 smartphones with USB Type-C.

USB Type-C Specification: A Quick Review

Most of you are familiar with USB technology, but there are some who are confused about the relationship between USB Type-C and USB 3.1; some even think that they equate to the same thing; when, in fact, Type-C is a separate specification. While the Type-C standard supports the USB 3.1 standard, it is more about the physical form factor than the transmission of bits and bytes. Essentially, Type-C offers an interface redesign with improved physical specifications for USB connectors, ports, containers, and cables. Type-C meets the demand for a lighter and smaller USB port, which allows for the design of more slender consumer electronic devices. Unlike previous models, USB Type-C interfaces are also symmetrical; which means that users will soon be able to plug their Type-C connectors into Type-C ports without having to first check the plug orientation or repeatedly jamming the plug into the port until it fits, as before.

USB 3.0 and 3.1 Connector Scale Drawing (Please click on image for enlargement.)

USB-IF (USB Implementers Forum) and IEC (International Electrotechnical Commission) expanded cooperation to finalize the latest USB Type-C specification, which features the following advantages:

- Smaller Form Factor – similar in size to the existing USB 2.0 Micro-B

- Scalable Power Charging – delivers up to 100 watts of power

- Extension – connector design scales for future USB bus performance

- Usability – reversible plug makes it easier to use

Type-C Certification Checkpoints

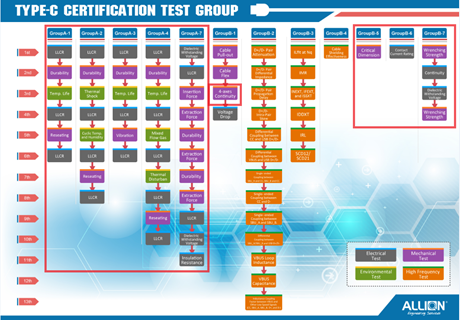

We begin with a brief introduction of the Allion Type-C Certification Test Group Chart. Type-C Test Groups are listed in the top row of this chart. Under each Test Group are one or more test items in color coded boxes, with each color mapping to a different test category: gray for electrical, purple for mechanical, green for environmental, and orange for high frequency testing items. Test requirements vary based on the USB certification class: receptacle (port), plug, and cable or adaptor assembly.

Allion Type-C Certification Test Group Chart (Please click on image for enlargement.)

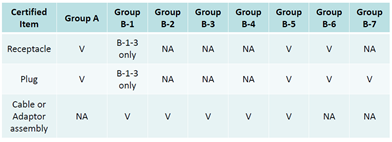

USB-IF Certified Items Chart for Type-C (Please click on image for enlargement.)

Based on the USB-IF Certified Items Chart above, for Type-C receptacles, all of Group A must be tested, just as with USB 3.0. However, for USB 3.0, all of Group B-1 must be tested, whereas for Type-C only B-1-3 (4-Axis Continuity), Group B-5 (Critical Dimension) and Group B-6 (Contact Current Rating) are required. As shown in the USB-IF chart above, Type-C plugs require all the same tests as Type-C receptacles, the only difference being that Type-C plugs require Group B-7 (Wrenching Strength Testing), while receptacles do not. For your reference, the required Type-C plug tests are outlined in red on the Allion Type-C Certification Test Group Chart above.

For cable or adaptor assemblies, Group A tests are not required, but Groups B-1 through B-5 are required. Group B-5 (Critical Dimension) testing is required because USB-IF has specified criteria for the over-mold thickness and width dimensions; if these measurements are exceeded then cable or adaptor assemblies will not pass USB certification. The USB-IF chart also shows that High Frequency tests (Groups B-2, B-3, and B-4) are not required for receptacles or plugs. Also, if the plating thickness test passes, there is no need for additional plating tests.

Type-C Certification Challenges

The following USB Type-C certification tests can be difficult to pass:

- 4-Axis Continuity Test (B-1-3)

This test is only required for USB receptacles and plugs; and the test method is slightly different when compared with USB 2.0 and USB 3.0.

• Mate the plug and receptacle and then apply 0.30 Nm of torque on the Right Angle Type of Top Mount (Reverse Type) or Mid Mount (Drop-In Type). For the Vertical Type, apply just 0.12 Nm of torque.

• The 4-Axis Continuity Testing for Type-C plugs is exactly the same as before, as 8 N of force must be applied and held for 10 seconds in all 4 directions, with the force removed between each change in direction.

• To pass the test there cannot be any flashover or breakdown.

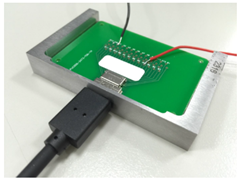

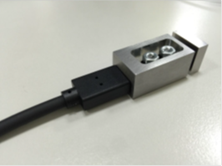

There is an additional difference between the Plug and Receptacle test, in that, the second-generation fixture front panel (see below right) can be removed, while the first-generation fixture (bottom left) does not have any panel at all.

Note: These must be standard test fixtures in accordance with USB-IF

(Please click on image for enlargement.)

First-Generation Fixture Second-Generation Fixture

- Wrenching Strength Test (Group B-7)

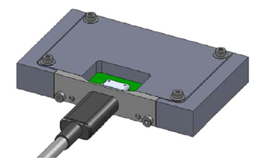

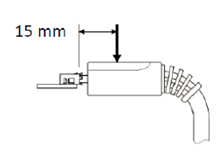

Generally speaking, the wrenching strength test should be repeated once. Use the Second-Generation Fixture to test the first time by applying 0.75 Nm of torque to the plug; which is accomplished by pressing down on the plug with a force of 50 N at a distance of 15 mm, as shown in the figure below. To pass this test there cannot be any flashover or breakdown.

(Please click on image for enlargement.)

• Test fixture to use the second time. (Please click on image for enlargement.)

A set of four new plugs are required for testing, since they often break due to the forces involved. Specifically, these tests mandate the application of 2 Nm of torque to the top and bottom of each plug (2 Nm = 100 N x 20 mm) and 3.5 Nm of torque to both sides of each plug (3.5 Nm = 175 N x 20 mm). Despite the possibility of breakage, you can be certain that damage is allowed, since failure can easily occur when a force of even 100 N is applied. No matter the outcome, the failure point curve must be provided to USB-IF.

- Durability & Insertion/Extraction Force Test (Group A-7)

This test is not that difficult to pass for the previous USB interface, but because the USB Type-C interface is made of plastic, it will wear down due to friction. Since the durability insertion/extraction tests are repeated 10,000 times, it is very important to check that the applied forces meet initial value requirements (Insertion: 5-20 N; Extraction: 8-20 N), and then decrease these forces after durability testing is complete (After Durability: 6-20 N).

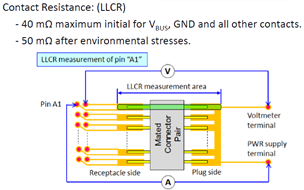

- Current Rating (T-Rise) Test (Group B-6)

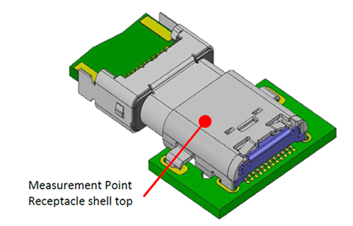

Note: The latest version of CTS requires one measurement point

The Current Rating (T-Rise) Test is also an area of concern for manufacturers.

So, how many measurement points are required for this test anyways?

Front View (Please click on image for enlargement.)

The first measurement point at the back is undetectable if the receptacle is the Top mount (reverse type). Basically, there is only one measurement point, but it can be adjusted in compliance with different types of connectors.

Type-C cables can support up to 3 Amps of power output, but require 5 Amps if they need to support PD (Power Delivery). Usually, when performing a Current Rating (T-Rise) Test, 5 amps are required for testing, regardless of PD support.

- Electrical Specification

USB Type-C electrical characteristics are defined by two specifications: Informative and Normative.

• The Informative specifications are guidelines rather than hard requirements. The compliance program will not test the informative specification items.

• The Normative specifications are the hard requirements and require design improvements if the device fails compliance testing. The raw cable electrical specs are included.

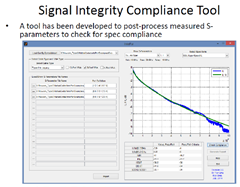

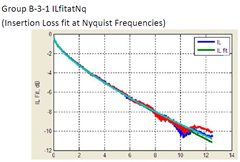

The S parameters of cable assembly are also informative, and the reason for testing is because we have to get the results exported into the SI MODEL in order to calculate frequency parameter and determine whether the cable assembly meets the specification by using INTEL’s Signal Integrity Compliance Tool. Overall, the actual export parameters are the six items of Group B-3.

(Please click on image for enlargement.)

Intel Software Screen

Actual Export Screen

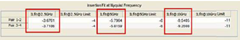

The values in three frequency bands, as given in the specifications, are noted in our reports, so customers quickly know if their outcome is a pass or fail, as shown below.

(Please click on image for enlargement.)

The table below shows USB 3.1 Gen1 and Gen2 in terms of Type-C to Type-C cables. Only the Insertion Loss Fit requirement is different; other values remain the same.

(Please click on image for enlargement.)

USB Type-C Certification Testing FAQ

Following are frequently asked questions about USB Type-C certification.

FAQ#1: CTS Certification Coverage

Since CTS 0.95 second edition, USB certification covers only mechanical (including environmental test) and electrical (including high-frequency) test categories. For USB Type-C receptacles, USB-IF launched many new kinds including the two most common: Top Mount (Reverse Type) and Mid Mount (Drop-In Type). For USB Type-C plugs, there are three kinds: Full Feature Plug & Cable, USB 2.0 Plug & Cable and Power-Only Plug & Captive Cable.

Three Kinds of Type-C Plugs (Please click on image for enlargement.)

USB Type-C defines three kinds of passive cable assemblies, as follows:

I. Standard Cable Assembly – Two USB Type-C to Type-C cables defined, USB 3.1 Type-C to Type-C cable assembly supports 5G of USB 3.1 Gen1 & 10G of Gen2, whereas the USB 2.0 Type-C to Type-C cable assembly supports HIGH SPEED. However, these two cable assembly types show little difference in their certification test requirements.

II. Type-C to Legacy Cable Assembly – Only USB 3.1 can support 10G version (for test requirement), that is, only USB 3.1 Gen2, no matter it is for Type-C to Standard A, Micro-B, or Standard cable assembly.

III. Type-C Legacy Adapter – USB-IF only accepts USB Type-C to USB Standard-A Receptacle Adapter (with 15 cm long cable) and USB Type-C to USB 2.0 Micro-B Receptacle Adapter, other types are not acceptable.

In short, CTS certification coverage includes Type-C connectors and passive cable assemblies, so that cables with an E-Marker are treated as passive cables.

Q: Besides USB 2.0 3A, which has no E-Marker, do the rest of the Type-C to Type-C cables need E-Markers?

A: Except for USB 2.0 3A, the other Type-C to Type-C cable assemblies require E-Marker chips.

The main feature of the Type-C standard is the new 24-pin connector receptacle.

The Full Feature port has both 22-pin and 24-pin variants, whereas the USB 2.0 port has both 12-pin and 14-pin variants. The figure below clearly shows the difference between the USB 2.0 plug with 9 pins and theFull Feature plug with 22 pins.

(Please click on image for enlargement.)

FAQ#3: Different Plug

Many manufacturers offer a Full Feature plug but not a USB 2.0 plug. So, is it possible to use a Full Featureplug to certify a USB 2.0 cable assembly? USB-IF says yes, but not for Type-C to Legacy. The Full Featureplug is not allowed to use before a public announcement is made, except as otherwise expressly provided in the revised specification.

FAQ#4: Durability

The ‘so-called’ durability test that runs over 10,000 cycles does not mean after 10,000 insertion/extraction cycles at one time. Instead, it means that before reaching 10,000 cycles the tester must ensure the insertion/extraction meets the specification. For example, the extraction force must be between 8 N to 20 N after the initial 1,000 cycles, then again after another 1,500 cycles of testing, for a total of 2,500 cycles, and then again at 7,500 cycles. Once the insertion/extraction tests pass the 10,000 cycle point the extraction force must be between 6 N to 20 N. This is the durability test approach currently defined by CTS.

Q: What is the current insertion force speed?

Q: What is the current insertion force speed?

A: USB-IF requires a cycle rate of 500 cycles per hour which is 500 ±50 cycles/hour in order to meet the EIA-364 test procedure of USB Electrical, Mechanical and Environmental Compliance Standards.

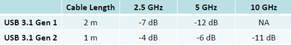

FAQ#5: LLCR Testing Point

LLCR testing point is a concern for most cable and connector manufacturers.

The latest version of the ECR testing points are provided for your reference:

(Please click on image for enlargement.)

The old LLCR measurement was made from female terminal point to paddle cards. The new LLCR measurement is made from the terminal point of the receptacle to the terminal point of the plug (not including the paddle card), as shown in the figure above. To pass the certification requirements, the original reading must meet the 40 mW specification and after the environmental test it cannot exceed 50 ±10 mW.

FAQ#6: Over-mold

(Please click on image for enlargement.)

Since the Type-C over-mold is thin and smooth, and therefore not easy to unplug, some cable vendors have asked if it would be possible to use a different style or shape to make it easier to unplug. Obviously, this is not acceptable to USB-IF, due to the dimension measurements of the cable certification.

FAQ#7: Vertical Type

One of the biggest problems when executing the certification test is when the test fixture has not yet been completed, while vendors have already developed the Vertical Type. As a result, the device cannot pass the 4-Axis Continuity or Wrenching Strength tests. This issue is under discussion within USB-IF, specifically what to do with the test fixtures to guarantee a certain degree of connector quality.

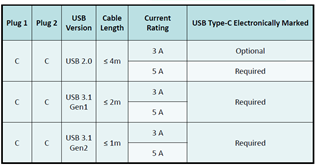

FAQ#8: Cable Length

Regarding the issue of whether it is necessary to include an E-Marker in a USB Type-C to Type-C cable, the table below shows that only the USB 2.0 version cable with a 3 A current rating can do without, all of the other Type-C cables require an E-Marker.

(Please click on image for enlargement.)

Concerning the cable length, is it measured from Plug to Plug or from SR to SR? USB-IF’s reply is that it should be measured from SR to SR, i.e., bare wire cable length. However, we have received different replies from USB-IF, so we still need further clarification about this issue. Nevertheless, it is certain that the PD receptacle is not accepted by USB-IF, as it may lead to a misunderstanding that 5A is accepted, when in fact it is not. For adapters, the maximum current is 3 A, since the original Type-C supports 3 A; also, the E-Marker is optional.

FAQ#9: High Frequency of Receptacle

With regard to the USB Type-C mated connector specification for SS-Informative, we are still in discussions with USB-IF about whether to change the Normative High Frequency test item. If it is not required to test, we are concerned that the receptacle will affect the function of the host device. When system companies wish to test it, Intel will ask for comments from leading system manufacturers. The parameter value will not be limited if required to test, in other words, there will be S parameter through tool transferring, and then transfer into SI MODEL and convert into datum once failed. Nevertheless, this part is not finalized yet. The test items for the connector will at least include the B3 Group tests that are required to test if change back to Normative.

FAQ#10: Trident LOGO

There are two misperceptions in the marketplace, the first being that a system must pass USB-IF compliance testing if its connector is to be certified. The second misperception is that the whole system does not need to pass compliance testing, even if its packaging is printed with a blue, white and red logo. According to USB-IF, it is not necessary for USB 2.0 cables to pass certification or display the USB logo. However, for products to have the 3.0 SS Trident logo, as shown in the figures below, products must pass USB-IF certification and compliance testing.

(Please click on image for enlargement.)

In other words, connectors must pass certification, but it is not necessary to have the whole system pass certification. For example, if a PC manufacturer would like to print the trident LOGO on the side of its product, connectors will have to pass certification, but the whole system does not have to pass certification. Depending on the product packaging, if it is printed with a blue, white and red logo, then it will need to pass certification. Generally speaking, systems printed with the SS Trident logo must pass certification, to ensure that they meet the USB specifications and interoperate with other USB devices.

USB Type-C Seminar – Market Analysis

Our USB Type-C seminar was very popular, with the number of applications exceeding the seminar capacity (120 attendees) for the first day of registration, so we offered a second day to allow more vendors to participate. The actual attendance rate for both days was about 80%, which indicates the level of interest in this topic. In addition, the return rate for our survey was also quite high, at about 85%.

According to our survey analysis, the main reason for participating in the seminar was to get an update on the latest cable/connector information and certification requirements. Regarding the overall evaluation of the seminar, the seminar attendees were very positive, with the majority expressing satisfaction with the seminar content and presentation. The survey feedback was also very constructive, which is a further reflection on the level of satisfaction with this event.

Since the majority of new cable products are USB 3.1 and USB Type-C, insiders are already aware of the massive business opportunities, especially cable & connector vendors, who have already been tracking these specifications for the past two years.

With Allion, you can save time and money, as we guide you through the maze of test requirements, so that you can quickly obtain USB Type-C certification. In addition, Allion has a dedicated USB-IF certification team in place with the required test equipment, so that you can save human resources and equipment purchase costs. Due to our familiarity with the certification process, our certification team can also quickly debug issues during testing and resolve them immediately, if possible.

Allion operates an independent Cable & Connector (C&C) Testing Center that is authorized by USB-IF as an official USB Cable Assemblies and Connector Lab, so we can assist your company with specification conformance, quality assurance, and additional advanced testing. This advanced testing includes electrical, mechanical, and environmental testing to ensure the best product quality and reliability. Moreover, our C&C Testing Center can perform sophisticated validation for many types of cables and connectors including: USB, HDMI, DisplayPort, MHL, and SATA interfaces. If you are interested in learning more about our comprehensive test services, please contact us directly at service@allion.com or read about our USB-IF Compliance Program on our website at http://www.allion.com/usb.html

(This article is written from the perspective of a professional lab, to share frequently asked questions about USB Type-C certification with the objective of enhancing industrial competitiveness and offering a platform to enhance communication and cooperation with our customers. Quality-Assurance services and technical consulting are also provided during product development and certification. If you have any questions relating to USB Type-C certification or other technical questions relating to testing and verification, contact us directly at service@allion.com)