Displays are indispensable to today’s electronic applications. Recent years have seen a surge in commercial displays, including video walls, digital signage, and touch monitors. They can be used in retail, restaurants, conference centers, shopping malls, hotels, and even outdoor and public transportation displays. As a result of the versatility of the application, there is a greater emphasis placed on the lifespan and durability of the product than before.

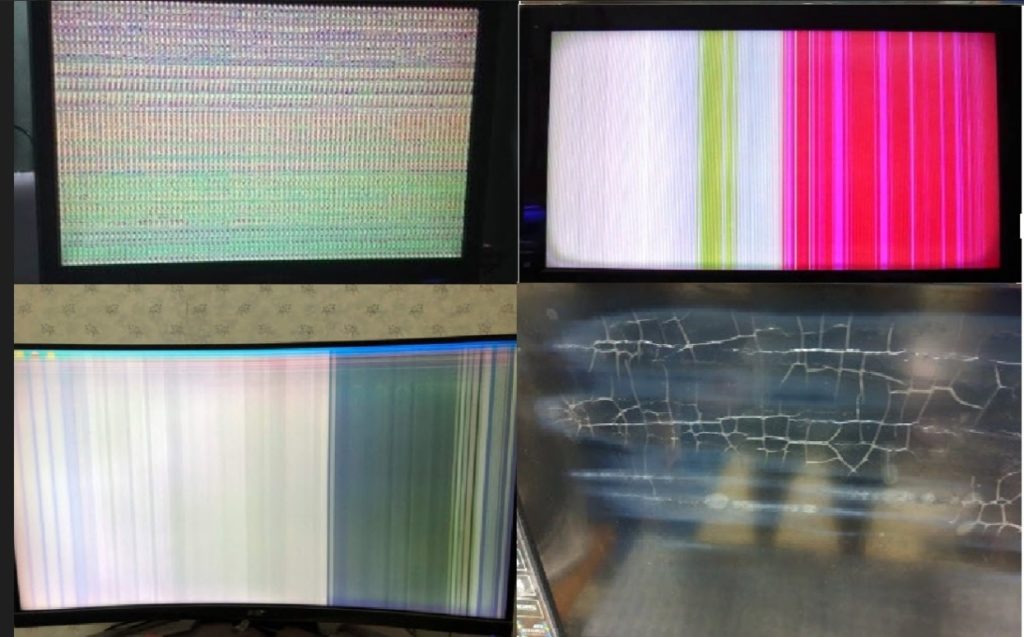

Examples of Factors That Affect the Life and Durability of Commercial Displays

In Allion’s extensive case studies, it has been discovered that many abnormal conditions occur after the screen has been on for a long period of time, including color cast, Mura or panel malfunctions, or even cracks inside the panel.

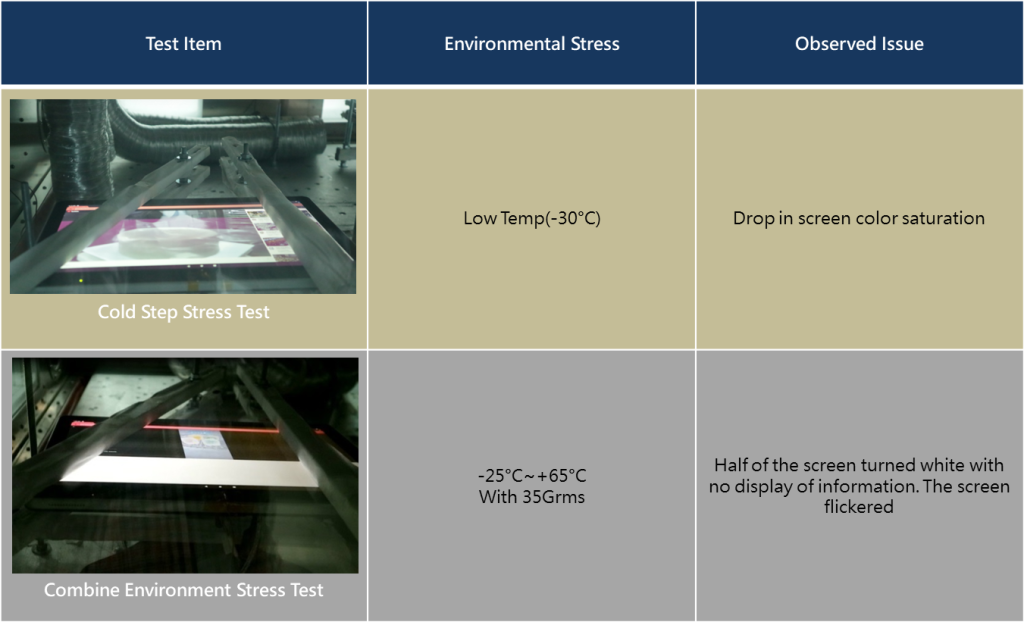

Traditional displays are typically tested under independent conditions, such as temperature, vibration, drop tests, etc. Commercial displays, however, are used more frequently and subject to temperature changes and vibrations simultaneously. Let’s consider a commercial display used in transportation. Allion’s professional team can provide HALT (Highly Accelerated Life Test), which provides early and middle-stage insight into the advantages and disadvantages of product design. Environmental stress is gradually increased through settings to reveal product weaknesses at different stages, such as design defects, manufacturing defects, and usage defects. Allion is thus able to provide customers with root cause analysis and troubleshooting advice, which allows the R&D team to modify the design or replace parts to make the screen more resilient and reliable.

Faster, Easier, Better: HALT Validation Service

Tests have shown that temperature stress and vibration stress affect the screen. During the low-temperature stress test, the screen color saturation dropped, making it difficult to identify the screen content. In another comprehensive high-low temperature and vibration stress test, the screen flickered and half of it became white with no information displayed. HALT verification solution identifies not only problems more quickly, but also risks that do not appear under a single environmental stress.

Due to Allion’s extensive testing experience and special testing equipment, it is able to provide the HALT (Highly Accelerated Life Test) solution, which has three major advantages:

Faster:

- Generally, reliability testing takes more than one month. With HALT testing, however, the testing cycle can be completed within 5 to 10 business days.

- Customers will be able to receive daily updates on the DUT’s progress and any problems that have been discovered during the testing process.

Easier:

- Using a networked application, customers are able to remotely monitor and control DUT statuses.

- In case a problem occurs during testing, we can provide the customer with the SOP for replacing the parts or PCBA, and we will assist the customer in replacing the part or PCBA on-site.

Better:

- The use of a magnifying glass to observe abnormalities on panel screens.

- Based on rich testing experience, we can provide R&D team with guidance for modifying designs or replacing parts.

- Allion’s extensive testing capabilities enable us to assist and arrange the second stage of HASS testing without modifying the HALT Chamber or equipment, thus eliminating hidden defects or identifying and resolving problems prior to shipping.

If you have any requirements or questions, please contact us.