As technology is rapidly evolving, monitors have been integrated into our daily lives. Whether we are working in the office, watching movies, or playing online games, monitors have become an indispensable part of our lives. Monitors are also the most commonly used product for commercial advertising. Most of these monitors are placed facing windows or outdoors, such as bus stops or walls.

Compared with indoor monitors, temperature changes greatly impact outdoor monitors. During the day and night, there will be different temperatures, as well as in the different seasons. When the temperature changes get too drastic or are too consistent for the long term, issues will easily arise with these products.

Can Outdoor Monitors Take Drastic Temperature Changes?

The following potential issues can occur when outdoor monitors take on drastic temperature changes:

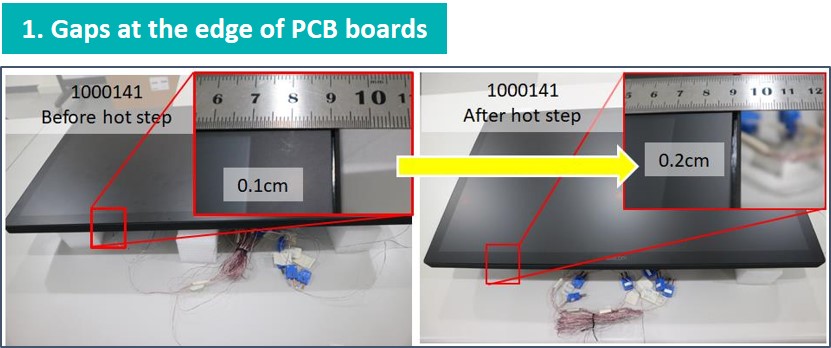

- Size and Shape Changes: Under drastic temperature changes, physical materials shrink and expand. This can affect product functions and performance, especially with applications that require precision.

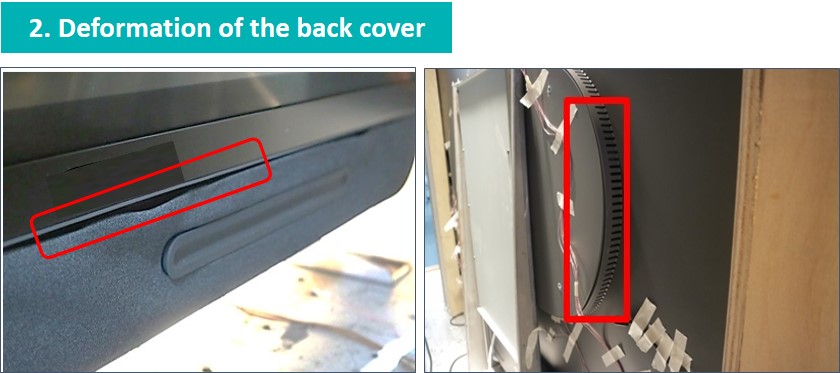

- Material Damage: Materials can become brittle, broken, or cracked under drastic temperature changes, leading to functionality issues.

- Durability: Materials have different capabilities of withstanding temperature changes. Some materials are more durable than others, and some will break down.

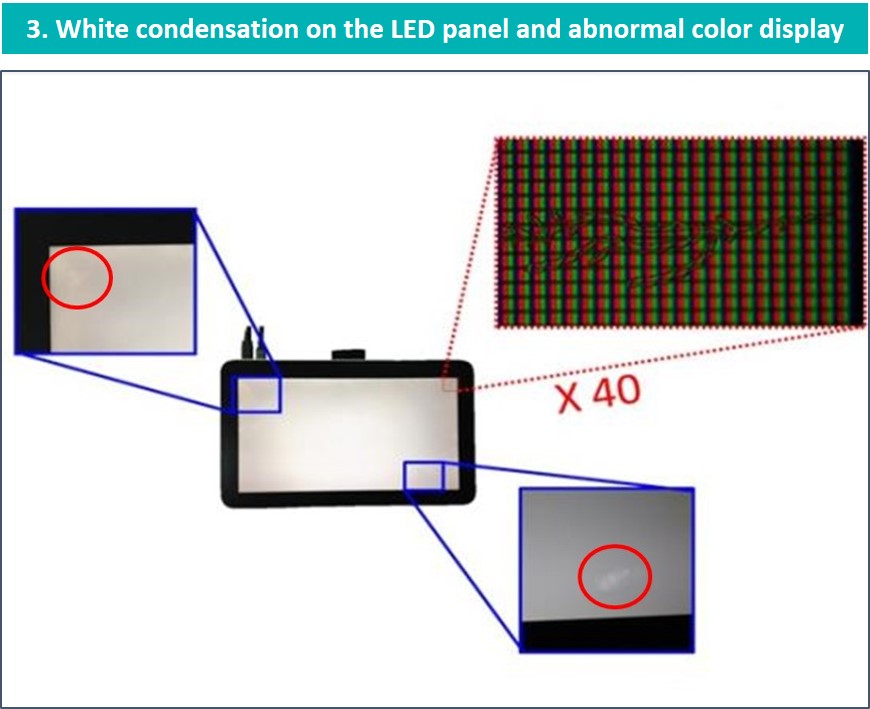

- Chemical Reactions: Materials can be sensitive to temperature changes, leading to chemical reactions, discoloring, or deterioration. This can affect the product performance.

- Joints: If a product is made up of multiple components that are joined or welded together, joints can become loose, cracked, or broken due to drastic temperature changes.

- Defects: Some defects are hidden when products are used under normal conditions, but once they are exposed to temperature changes, the defects start to affect the product and directly lead to product failure.

Thermal Shock Testing Solves Hidden Issues

To solve the potential issues mentioned above, we recommend that our clients conduct thermal shock tests before shipments to evaluate the products. The thermal shock test is commonly used to test materials, components, or entire products for their capability to withstand drastic temperature changes. The main purpose is to evaluate the stress caused by shrinkage, expansion, thermal stress, and condensation as a result of the temperature change. This method can effectively confirm the durability, stability, and potential issues of a material or product, making it possible for improvements and modifications to be made accordingly.

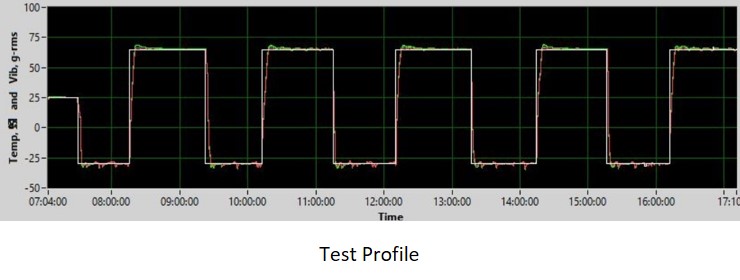

Allion has conducted many thermal shock tests on monitors and displays. The figure below shows the test conditions of a past client’s thermal shock test (-30°C to 65°C, 10 cycles)

Based on our experience, these are the common issues we find after testing:

In this industry, user experience has always been the top focus among manufacturers. The issues with temperature changes will only make the user experience even worse, ultimately damaging brand image and product reviews.

Faster, Easier, Better! Your Most Trusted Monitor Testing Consultant

Allion has decades of experience and expertise in testing audio and speakers. With a wide range of testing equipment and professional instruments, we are confident in providing clients with the best evaluation for your products, identifying issues one by one.

Faster

With our rich testing experience and collection of testing equipment, we can provide clients with fast and accurate testing planning that effectively shortens the schedule. No matter what the product stage is, Allion is able to provide our clients with fast and accurate results.

Easier

By implementing AI and automation solutions, Allion ensures that audio and speakers test is “qualitative, quantitative, and reproducible”, helping our clients to improve product performance in a more efficient manner.

Better

With more than 30 years of expertise, Allion has many professional teams with the knowledge to design quantitative testing methods and user experience verification testing. We also know how to design quantitative tests and user scenario simulations, allowing our clients to comply with requirements and user expectations.

If you have any questions about display devices or its ecosystem, please feel free to contact us through the online form.