Understanding Cable Strain Relief (SR) for Inter-device Connections

In the era of advanced information technology, 3C products have deeply penetrated into everyone’s daily life. Cables, as one of the essential accessories in these products, play a crucial role in connecting different devices to facilitate data transmission and display. For example, users use cables to connect devices such as smartphones and laptops to projectors and monitors for presentations or video watching. Corresponding to various products, there is a wide variety of cables, including HDMI, USB, DP, and other specifications, most of which include SR components.

The “SR” in Cable SR stands for Strain Relief, referring to the part between the connector and the cable in the cable. The main function of this important structure is to eliminate the pressure on the cable during use, reducing wear and deformation, known as “stress relief”. Stress relief effectively prevents the cable from breaking at the junction with the connector, avoiding affecting the cable’s lifespan. It also ensures that the connector does not lose its connection function due to the cable’s pulling or bending during use, affecting the cable’s transmission efficiency.

SR location diagram and scope of action

Potential Risks

After multiple uses, cables may experience hidden damages that users are unaware of since most components are usually not visible and can only be detected through careful inspection or testing. For example, when cables pass through walls or are connected in narrow, crowded spaces, the solder in the connectors may loosen, causing poor contact or short circuits. Transmission media like copper or fiber optics may also break due to stretching or bending, affecting transmission efficiency or quality.

Even if the cable’s sheath and casing appear to be in good condition, without obvious damage or deformation, fragile internal components may be damaged, leading to decreased cable performance or failure. These damages could have serious consequences, ranging from abnormal connection functions and the inability to use devices properly to risks such as electric shock or even fire.

Poor strain relief may lead to the following conditions:

1. Internal wire breakage

2. Damage to the internal wire insulation causing a short circuit

3. Breakage of the cable’s outer sheath

Among these, condition 2 is the most dangerous. If the outer sheath is undamaged but the internal insulation is broken, it is difficult to detect with the naked eye. A short circuit could lead to a fire, resulting in irreparable losses!

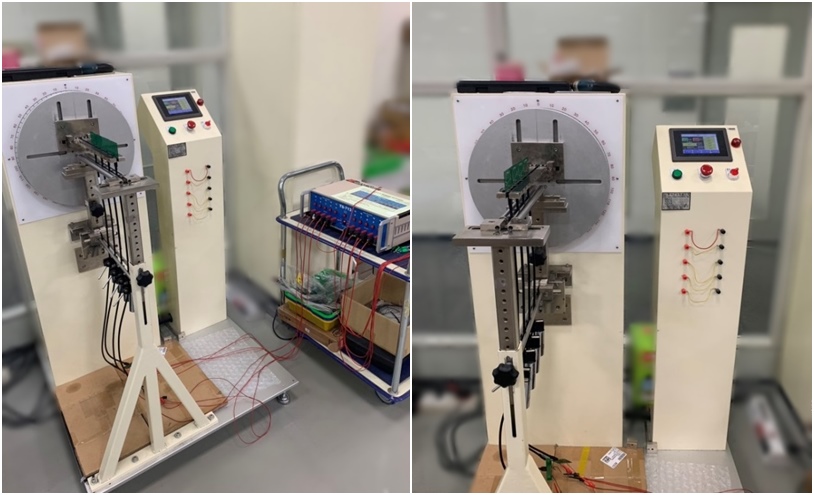

Faster, Easier, Better: Allion Cable Consultation Service

Allion has dedicated flexing testing equipment for rigorous quality testing of cables. During testing, the cable undergoes multiple swings at specific angles, simulating the bending and twisting that users subject the cable to in daily use. This verifies the cable’s lifespan, ensuring it can be used for an extended period without failure. Additionally, the testing equipment is equipped with an instant breakage tester to monitor signal transmission conditions. If an instant breakage is detected, it indicates that the internal wires may have loosened or broken, affecting the cable’s transmission effectiveness.

Through our cable testing consulting services, the integrity and stability of internal wires can be confirmed, ensuring cable quality and performance. We also conduct comprehensive inspections for external damages such as sheath ruptures or connector deformations.

Allion has accumulated extensive project experience in cable-related verification. Our advantages include:

Faster:

Allion has complete cable & connector testing equipment and environment, covering electrical signals, mechanics, and reliability, providing one-stop comprehensive services.

Easier:

Allion has well-established verification experiments, conducts swing tests on cables according to the EIA364-41E standard, and provides professional engineering consulting and efficient solutions to quickly resolve product issues.

Better:

Allion has accumulated over 30 years of rich verification experience. In addition to normal standard tests, we can also customize tests according to customer’s special specifications and provide professional fixture designs to enhance overall testing.

If you have any requirements, please contact with us.