Can’t Understand the Complex Characteristics of High-Frequencies? Is Product Verification Taking Up Too Much Time?

In Part 1, we discussed the challenges and risks of high-frequency connectors. The characteristics of low-frequency connectors do not need much consideration during design, but high-frequency connectors and their characteristics are very complex, and mechanical engineers often do not have experience with these products. Because of this reason, it usually takes a long time to design and verify high-frequency connectors and it’s very difficult to effectively identify issues during product verification.

Potential Risks of High-frequencies

Allion has a complete range of testing equipment and has decades of testing experience. For this article, we’ve summarized the potential risks of high-frequency connectors.

1. Insertion Loss

Signal attenuation increases when the insertion loss is too large, affecting the transmission efficiency such as distance and bandwidth.

2. Return Loss

Signal reflection and interference are caused when the return loss is too large, affecting signal quality.

These risks could potentially cause data to be transmitted at a lower frequency and allow for the bit error rate to rise. This means that the performance of the entire server will be affected.

Engineers always want to know the solution when insertion loss and return loss tests fail. They may want to observe the TDR, hoping it will give them answers. However, it’s tricky when the TDR is already in compliance with the standards. So what do you do then? Allion has decades of testing experience with clients and projects and we want to share our knowledge with you. Below are some examples to help.

Case Study

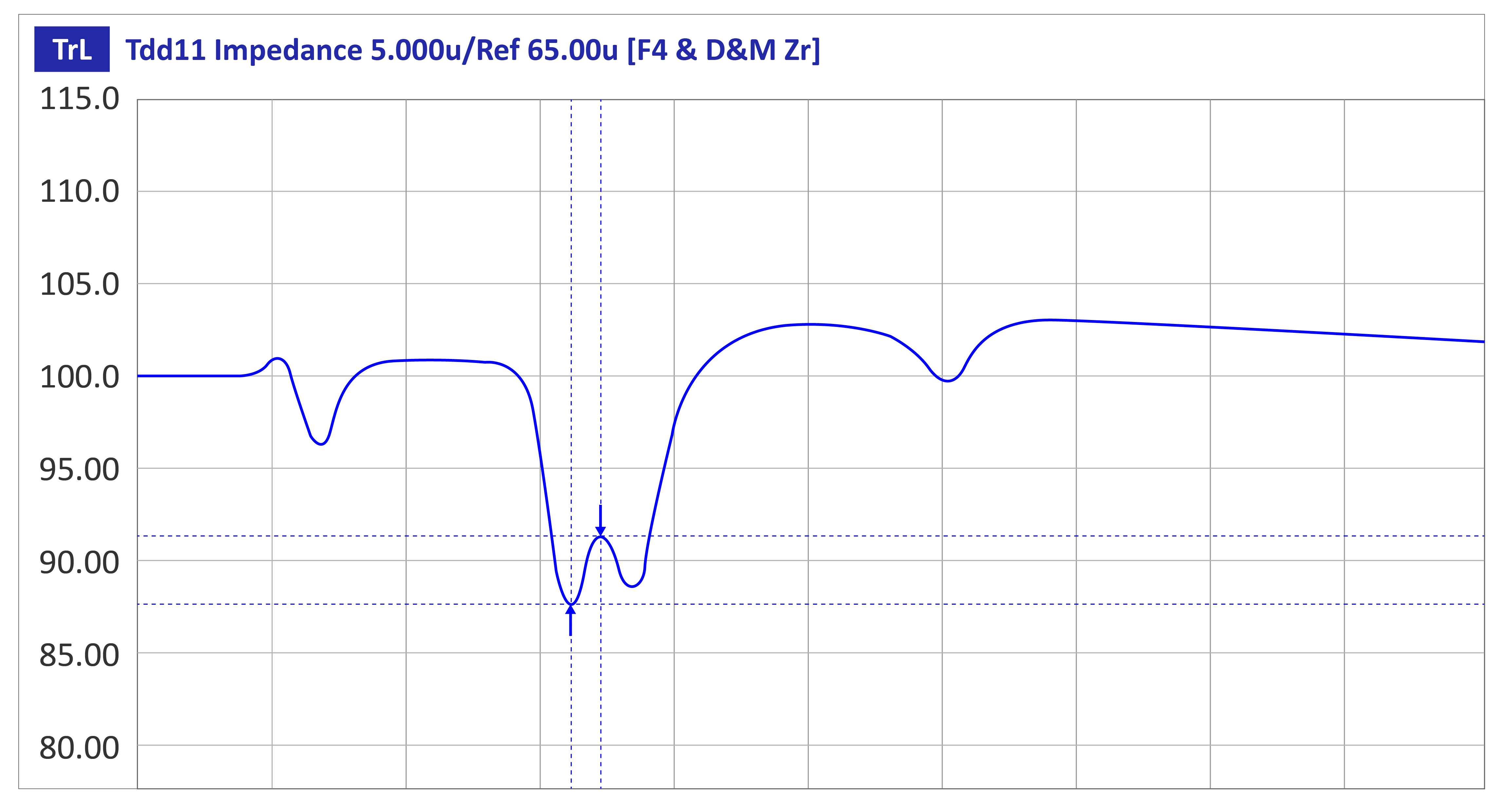

Figure 1 shows a TDR test for a USB 4.0 connector mating. According to USB 4.0 specifications, the impedance values are 85 Ω ± 9 40ps (20%-80%) rise time. It can be seen that the TDR measurement complies with the standards, but the USB 4.0 IRL did not pass the requirements. For Allion’s team, there’s room for improvement with these TDR curves. The number of signal reflections can often point out the quality of the S parameters. Although the TDR results comply with the standards, there could be multiple signal reflections due to the impedance. Therefore, solving the issue regarding signal reflections could also solve the issue of IRL failure.

Figure 1: TDR test for USB 4.0 connector mating

Faster, Easier, Better: The Most Trusted High-frequency Connector Testing Consultant

Allion is very familiar with high-frequency connectors and has lots of experience with client projects. We are an internationally certified laboratory with the following advantages:

Faster

Allion has more than 30 years of professional experience, multiple professional teams, various testing environments, and high-quality testing equipment. This allows us to provide our clients with fast and accurate results.

Easier

Allion can provide clients with test fixture design, product testing, and even strict quality control.

Better

Allion has decades of experience with testing, analyzing test results, and helping clients solve issues.

If you have any further needs for testing, verification, or consulting services, please feel free to explore the services or contact us through the online form.