In an era where smart devices fill our homes, charging cables have become essential daily items. With the ongoing specifications revolution, charging cables are gradually shifting towards the adoption of the unified Type-C standard. USB charging cables have transformed into one of the best-selling products in the mainstream market. To maintain competitiveness, products not only need continuous innovation and optimization in performance but also must ensure durability and safety. This is crucial to instill confidence in consumers when purchasing and using them.

Application Safety Risks and Solutions for USB Charging Cables

Charging our devices before bedtime has become a routine for modern individuals. However, during prolonged use, charging cables can be subjected to bending or twisting forces, leading to the breakage or damage of the core wires. This can result in a decline in signal quality and even pose safety issues such as short circuits, leakage, or combustion.

Allion’s analysis of market complaints reveals a significant proportion of cases arising from poorly designed or manufactured USB charging cables. Consequently, these issues manifest shortly after product use, severely impacting consumer experiences and triggering a surge in product returns and exchanges.

Even if the appearance of the charging cable appears normal, issues can arise when connecting between devices, displaying “USB device not recognized” notification, hindering both transmission and charging. In such instances, consumers might try bending the transmission cable at a certain angle, potentially restoring the signal and functionality. As a result, when facing similar situations in the future, users may resort to bending the charging cable again to restore its functionality.

The problems mentioned above all result from core wire damage leading to the interruption of transmission signals. There are two types of signal interruptions:

1. Conditional Signal Interruption:

The cable experiences signal interruption only at a specific angle. This situation arises because the core wire is damaged, causing a temporary signal pathway to appear when pressure is applied at a particular angle.

2. Continuous Signal Interruption:

The cable has suffered core wire damage or even breakage during use, resulting in a continuous signal interruption at any angle.

Cases of this nature are challenging to identify from the appearance and typically manifest during usage. When users encounter conditional signal interruptions, they tend to apply pressure and bend the cable to temporarily restore functionality. This practice can lead to long-term issues such as outer layer damage, exposed core wires, and short circuits.

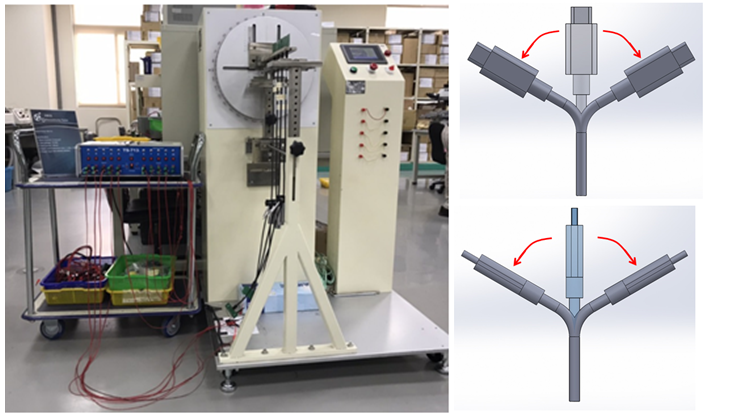

Allion consulting team has supported numerous cable suppliers, possessing institutional equipment compliant with the EIA-364-41E testing specifications and instant circuit-break instruments for signal measurement. Addressing the aforementioned issues, we can monitor and conduct signal tests during repeated cable bending tests (Cable Flexing Test).

Through testing the number of repeated bends, we verify the durability and reliability of the cables. Allion has also assisted various brands in defining Test Specs, aiding in quality improvement and increasing consumer purchasing confidence.

Faster, Easier, Better: The Most Trusted Cable & Connector Consulting Service

As a professional testing and consulting laboratory, Allion not only assists cable manufacturers in obtaining USB certification but also helps refine verification plans for products. Additionally, we offer customized experiment testing and improvement suggestion analyses tailored to customer requirements. Our engineering consulting provides efficient solutions aligned with the needs of each development stage, covering product design, quality testing, and standard verification. We synchronize with various standard association specifications.

Allion further extends its services to include the following testing capabilities, aiding clients in mitigating potential issues, enhancing product quality, and reducing the risks of product recalls and returns.

- Testing plans and condition recommendations

- Compatibility and functionality testing

- User experience testing

- High-frequency signal testing

- Durability testing

- Competitor analysis and quality improvement consulting

Faster:

Drawing on our extensive experience in testing services and collaboration with experts in relevant technical fields, the Allion testing team, backed by an accumulated technical database, specializes in providing prompt answers and tailored consulting services for the initial design and development of transmission cables. We address technical, safety compatibility, and regulatory requirements for your products, ensuring the highest quality assurance.

- Abundant equipment and experience for the rapid provision of verification plans

- Swift assistance in obtaining standard certifications (USB) for our clients

Easier:

Allion testing team possesses in-depth knowledge of various transmission cable products, with rich expertise and extensive experience in high-frequency testing. This enables us to quickly identify product defects and failure issues during the product engineering sample testing process and provide corresponding solutions. Allion ensures that each verification assessment exhibits characteristics of “qualitative, quantitative, and reproducible.” Our services assist you in enhancing product quality and overall performance more straightforwardly.

- More accurate test results

- Professional issue isolation and debugging support facilitate seamless product development

Better:

Allion’s professional testing team is the ideal partner for distributors and manufacturers, offering comprehensive support services. We provide relevant applications during the early design stages, incorporating the right association standards. Finally, we conduct rigorous testing quality during product mass production verification. This helps downstream distributors or brand manufacturers ensure safety, reliability, and compatibility, providing consumers with confidence and safety in product usage.

- Better and more comprehensive assistance in establishing supply chain quality management

- Better and more comprehensive user scenario simulation testing

If you have any requirements, please contact with us.