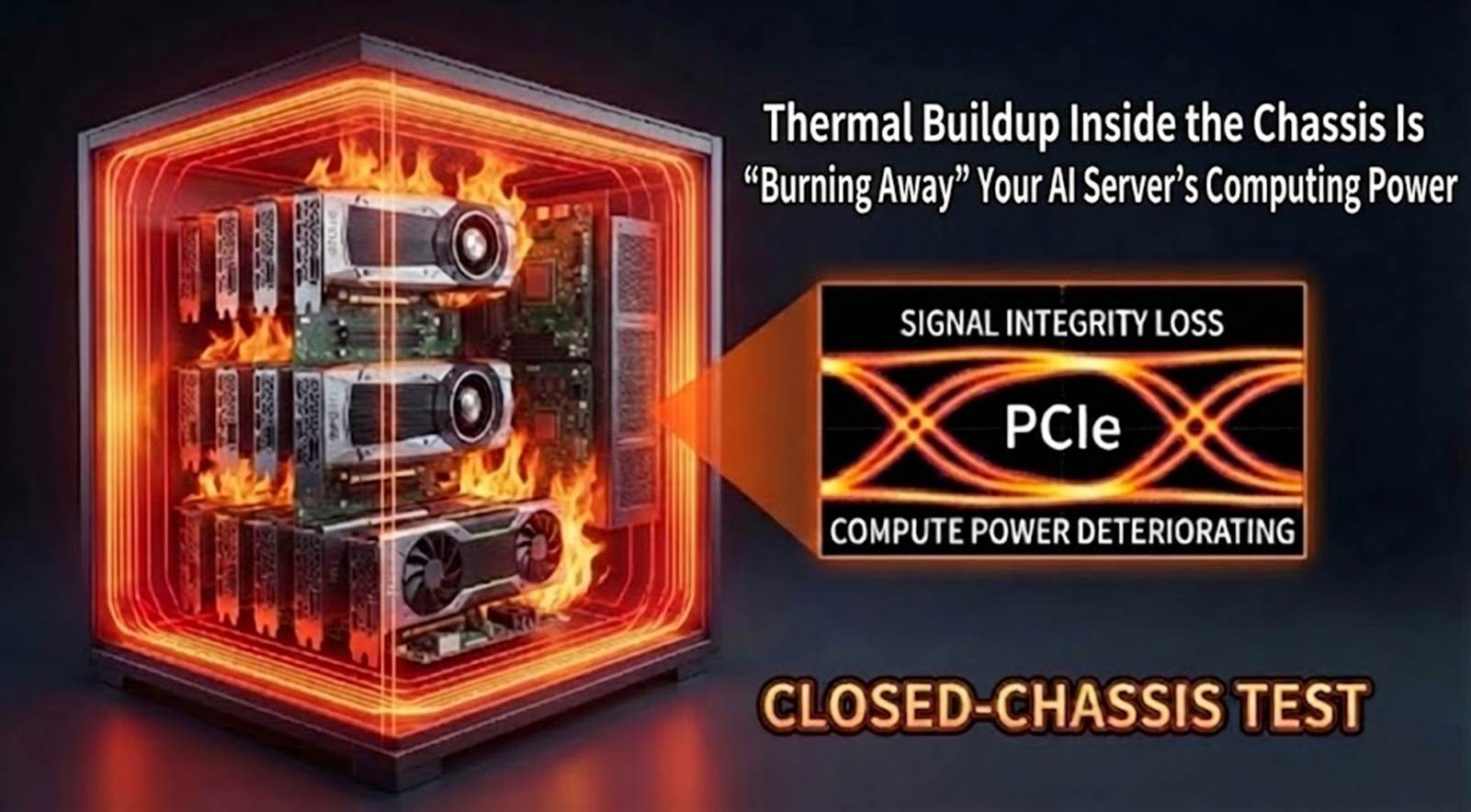

What’s happening inside the chassis is silently degrading your AI server’s computing power.

—— Only Closed-Chassis Testing can expose true stability.

In the industry, servers are typically validated in open environments with ample cooling and ideal laboratory conditions. Under such circumstances, passing tests is relatively easy, and preliminary results often indicate everything is “normal.”

However, once the server enters real-world deployment—mounted in a rack and operating continuously under high workloads—the internal temperature gradually rises. Airflow becomes restricted, heat dissipation weakens, and thermal energy accumulates inside the chassis. Over time, the server effectively operates like an oven.

This is the true stress scenario that challenges the performance and durability of AI servers.

Open Environment vs. Closed-Chassis Reality: Why Do AI Servers Behave So Differently?

AI servers are fundamentally different from traditional enterprise servers due to their high-risk architectural characteristics:

Key Characteristics of AI Servers

- High GPU density with complex riser architectures

- Introduction of ultra-high-speed PCIe Gen6 signaling

Resulting SI Risks

- Multi-hop signal paths where connectors and cables become weak points

- Even minor impedance changes can significantly degrade performance

In such architectures, a single poor-quality PCIe link can degrade the performance of the entire AI server—not due to component failure, but due to computing power silently deteriorating under heat.

Under sustained high temperatures, PCIe signal integrity, error rates, latency, and eye margins may all begin to degrade.

Traditional open-air validation cannot reveal these risks because it does not reflect real operating conditions.

In the era of large-scale AI, testing must be performed with the chassis intact.

To uncover real-world stability, there is only one answer:

Closed-Chassis Testing — Seeing Real Risks Under Real Stress

Allion’s Closed-Chassis Testing evaluates servers in their fully assembled, operational state—faithfully reproducing real customer usage scenarios.

Test results show that when servers run for extended periods and heat accumulates inside the chassis, issues emerge that are nearly impossible to detect in conventional labs, including:

- Increased signal attenuation and reduced transmission stability

- Greater jitter, higher bit error rates, and increased latency

- Reduced eye margins and significantly lower reliability

These are the true long-term stress factors systems face in the field.

Closed-chassis testing enables early detection and correction—preventing hidden risks from reaching mass production or customer environments, where they could result in massive losses and erosion of brand trust.

Why Closed-Chassis Testing Is Rare — and Difficult

Simulating real usage requires burning in servers while fully sealed, which means:

- Test fixtures must be redesigned and fully automated

- No manual intervention is possible once placed in a thermal chamber

- All measurements must be completed unattended under high temperature and long duration

This level of testing requires not just equipment, but methodology, architecture, and experience.

Allion Golden Methodology – Server Testing Flow (Burn & Measure Architecture)

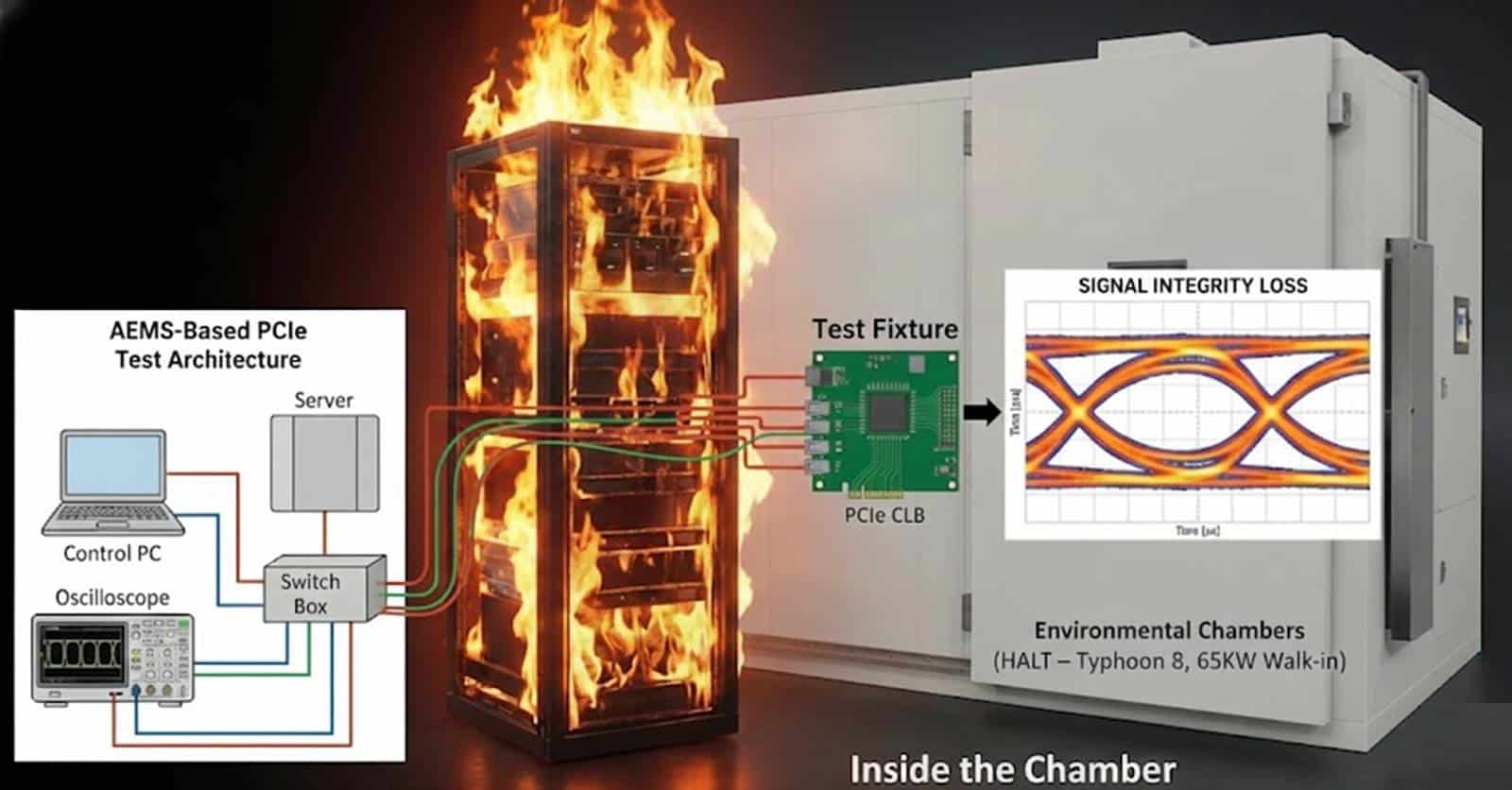

- Burn & Measure Architecture Objective: Operate the server under high computational load and high-speed data transmission inside a closed chassis, while simultaneously observing “Signal Integrity (SI)/Bit Error Rate (BER)/Jitter” under real conditions of heat, power fluctuation, and electrical interference.

- Issues Revealed: Test results can reveal signal edge degradation under high-temperature conditions, variations in connector impedance, and the compensation limits of Retimer/Redriver components when subjected to thermal stress.

- Automation for Full Coverage: With AEMS automation, every lane can be fully tested under prolonged high-temperature stress, with data transmitted to an external control PC for analysis—ensuring laboratory data truly reflects real operational behavior.

Closed-chassis testing is the only way to observe real SI performance degradation and prevent silent loss of AI computing power under heat.

From the Lab to the Field – The Future of Server Reliability Validation

Traditional Manual Testing:

- Cannot realistically reproduce operational risk

- Requires disassembly and repeated cable reconnection

- Test cycles of 40–60 days

- Coverage often reduced to 20–50%

- Realistic simulation of high temperature and high load

- Long-duration tests without human intervention

- Completion within days

- Full coverage of every lane and temperature condition

Let laboratory data reflect real-world behavior, not just attractive numbers.

🏆 The Value of Closed-Chassis Testing

✅ Reveals signal degradation and throttling under real thermal stress

✅ Identifies failure points early, reducing RMA and maintenance costs

✅ Shortens development cycles while improving coverage and accuracy

✅ Demonstrates true reliability and market competitiveness

🌟 Avoid Servers That “Appear Normal While Quietly Burning Inside”

An AI server may look normal externally, but inside a sealed chassis it may be experiencing:

- Signal attenuation

- Accumulating errors

- Performance degradation

- Silent loss of AI computing power

These issues occur gradually and invisibly.

The greatest risk is not sudden failure—but progressive degradation under sustained heat.

Only by validating systems in their original chassis configuration can enterprises truly understand AI server stability and prevent computing power from being quietly consumed.

If you have any questions about AI servers or require further assistance, please feel free to contact us via the online inquiry form below.