Allion Consulting Insight

The rise of AI technology has become one of the hottest topics in recent years, driving a wide range of derivative applications that continuously enrich and diversify product functionalities. To embrace this wave of AI-driven innovation, manufacturers are facing increasingly complex challenges in product specifications and overall design architectures.

This article explores a practical case from an HMI product manufacturer, showcasing how Allion’s expert consulting services create tailored intelligent inspection solutions. By addressing production line management issues and implementing comprehensive quality tracking, clients have realized remarkable benefits, including a 3X boost in manufacturing output.

>>>Got a question? Click here to consult with Allion’s experts. <<<

New Challenges from Cross-System Integration: HMI Manufacturers Confront Dual Pressures of Quality Assurance and Multi-Application Integration

In this case study, the client is a Human Machine Interface (HMI) product manufacturer, specializing in transportation dashboards and industrial control tablets. Traditionally, these products were designed for single-task functions with minimal integration requirements. However, with the rise of smart applications, HMI devices must now seamlessly support diverse applications, interconnect with other devices, and even enable wireless networking. This shift has made cross-system integration a critical issue for HMI smart applications, while at the same time presenting manufacturers with increasingly complex and demanding challenges in production line quality testing.

Challenge 1: Increased Testing Time

With the diversification of product functionalities, the time required for product testing inevitably rises. Without improvements in testing efficiency, this will inevitably impact both output and overall production capacity.

Challenge 2: Multiple Testing Items and Inconsistent Manual Methods Affect Quality Inspection Results

As product functionalities expand, traditional manual operations can no longer meet current testing demands. Manual testing cannot guarantee that each operation is performed consistently in a qualitative, quantitative, and reproducible manner. This inconsistency makes it difficult to accurately identify issues, often resulting in discrepancies in testing outcomes.

Challenge 3: Ensuring Effective Documentation of Manual Testing Processes and Results

Recording testing results is not only essential for determining whether a product can be shipped, but also plays a key role in facilitating problem resolution. Manual documentation, however, is time-consuming and carries the inherent risk of errors.

Golden Methodology x AI Solution: Bridging Production Testing Gaps with Comprehensive Functional and System Integration

To address the challenges faced by the client, Allion’s consulting team conducted in-depth interviews to gain insights into operational processes, manufacturing information workflows, and critical pain points. Following a comprehensive project evaluation, we developed a tailored solution covering product verification, testing, operation, evaluation, and data integration, enabling the client to deploy a smart production line inspection solution.

Robotic Arms and Operating Fixtures

Robotic arms can simulate human hand motions and, in combination with single- or dual-finger fixtures, execute a range of user operations on the screen, including tapping, double-tapping, long pressing, sliding, zooming, rotating, gripping, and other customized actions. They can also control the rotation of physical buttons to inspect product functionality.

Visual Recognition

The smart camera integrates visual recognition software, which compares the recorded footage with the image database to recognize objects, images, or text while responding appropriately, and determines whether the displayed interface meets normal functional standards.

Stationary Platforms and Mobile Mechanisms

Products can be secured on the testing platform and positioned at the test location through the movement of mechanical fixtures. In addition to enabling batch placement for testing, operators are not required to remain stationed in the area, allowing for more efficient workforce allocation.

Data Integration

Integrating production data from ERP, MES, and other systems ensures smooth information flow, enhances operational performance, and supports the goal of unified management.

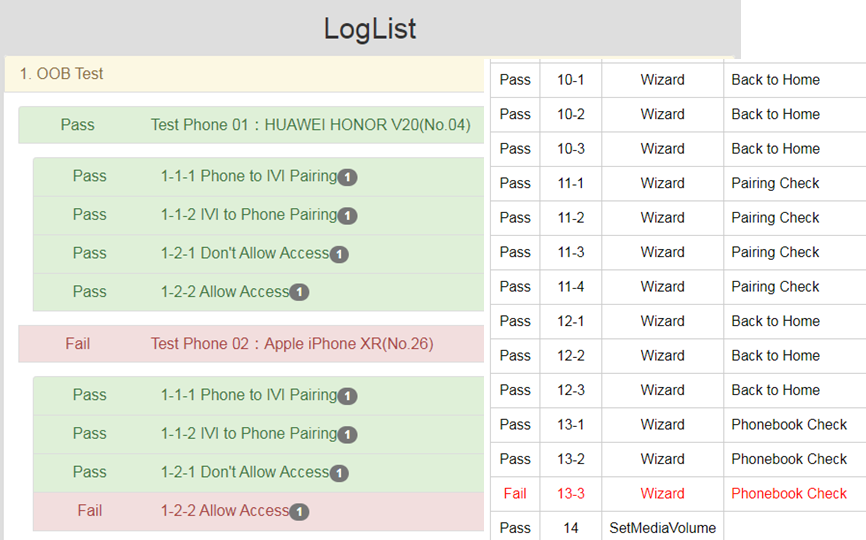

Log/Report System

All test execution actions, functional display records (photos and videos), and test timing are comprehensively recorded in the Log/Report system. This ensures that test reports are not merely a record of pass/fail results, but also serve as a critical reference for product improvement and quality traceability.

Explore More: AI Test Solution (ART)

Implementation Benefits

By adopting the AI Testing Solution (ART) functional modules, the client not only integrated intelligent testing capabilities into their previously fully manual operations but also achieved comprehensive improvements in overall production line efficiency and product quality. The specific benefits are summarized below.

Continuous 24/7 Operation, 3X Production Growth

Based on an 8-hour workday, the client could previously produce up to 40 HMI units per day. With the adoption of intelligent testing, they can now operate around the clock, resulting in a marked increase in production line efficiency and a threefold growth in daily output.

Ensuring Consistent Testing Methods for More Stable Operational Quality

Compared with manual operations, AI testing solution helps ensure consistency in testing methods. In addition to significantly reducing human error, it stabilizes operational quality and allows production line personnel to be deployed more efficiently and flexibly.

Integrated Production Line Testing Management for Comprehensive Product Quality Traceability

By eliminating manual record-keeping, all test results are effectively documented through the AI test solution, fully implementing product quality traceability. This enables the client to conveniently manage and easily access all relevant testing information.

Related Article

Time to Market with Quality! Allion Builds the Path to Success for Your Products

Allion has developed multiple functional modules, including robotic arm applications, finger/gripper fixtures, mechanical design, visual recognition, script editing, peripheral device integration, and information system integration. These modules can be customized to meet individual client requirements, creating an intelligent production line test platform that enhances both operational efficiency and product quality.

If you are struggling with product inspection quality and production line efficiency, feel free to contact us through our inquiry form. The Allion consulting team is ready to provide customized solutions to help your products excel in a highly competitive market.