The AI Era Demands Servers That Are Fast AND Stable

Driven by the growth in AI demand, AI servers have become the core computing infrastructure in data centers. From large-scale cloud data centers to edge computing, each AI server handles millions of data exchanges and model computations, enabling a wide range of everyday applications, including large-scale image analysis, edge computing, and natural language processing. These servers are also widely deployed in smart cities and IoT applications.

During operation, every high-speed cable behind a server provides efficient, stable, and workload-capable data transfer. In such high-frequency, long-duration operating environments, even a single high-speed cable that has not undergone rigorous verification can become a hidden risk affecting system stability.

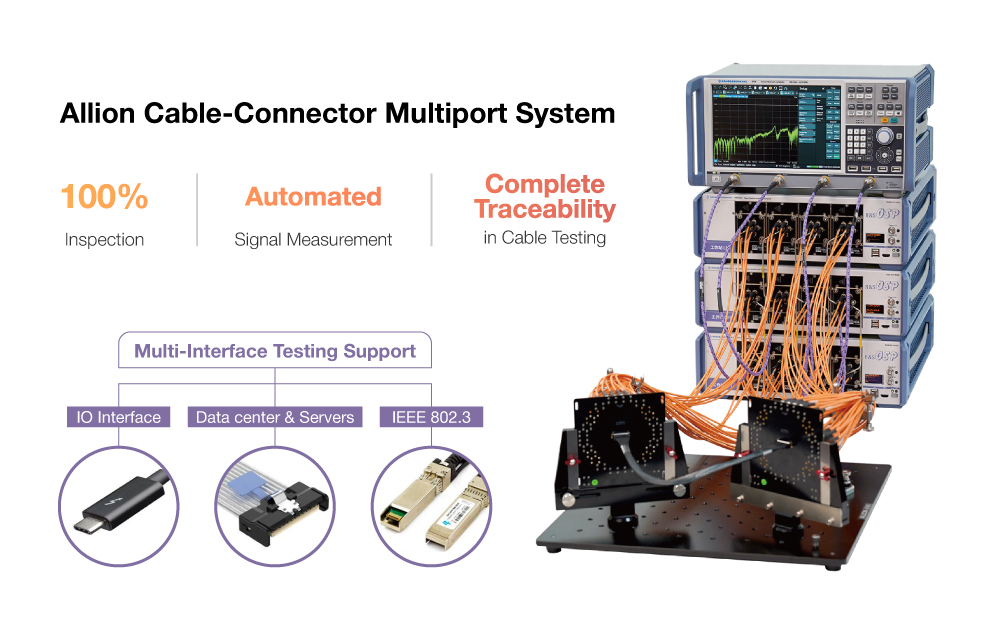

ACMS 100% Inspection × Golden Methodology

As the examples above show, no cable inspection on the production line can be overlooked. Allion has years of experience in high-speed signal and AI server validation. Through continuous innovation and the deployment of the Golden Methodology, Allion developed the ACMS (Allion Cable-Connector Multiport System) testing platform, specifically designed for mass production.

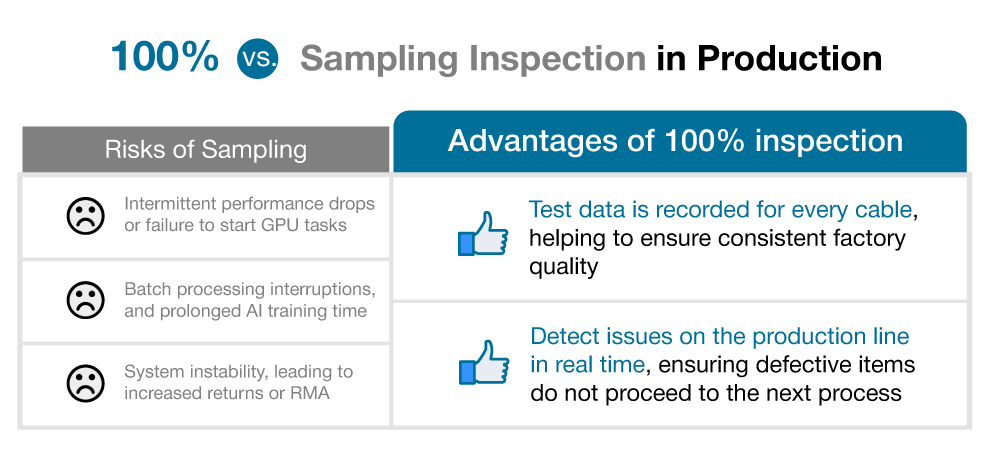

ACMS can be applied to the production line to perform fully automated signal testing and quality tracking for every high-speed cable, achieving 100% inspection with traceable records, effectively preventing issues.

Why “100% Cable Inspection” is Critical for Procurement?

◆ Reduce After-Sales and Maintenance Costs

Fully inspected cables drastically decrease returns, repairs, and on-site replacements caused by connection issues. Preventing problems upfront is more time- and cost-efficient than addressing them afterward.

◆ Enhance Customer Trust and Brand Image

When server stability is verified in the market, brand reliability and reputation naturally improve.

◆ Shorten Project Deployment Time

No need to spend time troubleshooting unstable connections, allowing smoother project delivery and faster deployment.

◆ Establish a Traceable Quality Mechanism

Every cable has a unique ID and test data, providing clear traceability of origin and quality.

From Quality Assurance to Brand Trust: A New Standard for AI Server Stability

The computing performance of AI servers depends on the collaboration of hundreds of high-speed cables. With ACMS, “100% inspection” becomes a guarantee. End customers can be confident that every server not only delivers high performance but also offers long-term stability, zero complaints, and low maintenance costs. Reliable connection quality is, ultimately, a brand’s strongest competitive advantage.