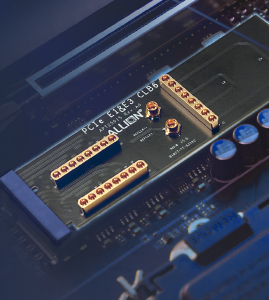

A leading datacenter supplier approached Allion for support in developing a test fixture tailored to their unique PCIe Gen 6 connector. Due to the evolving specifications of PCIe Gen 6, off-the-shelf solutions could not meet the precision and compatibility needed for their signal validation process. The client faced challenges stemming from undefined test conditions, such as total loss budget, de-embedding methods, and specific connector design requirements.

Allion’s Solution

Understanding the critical need for early planning, Allion engaged with the client during the initial requirements analysis phase. By collaborating closely with the customer’s engineering team, Allion was able to define key parameters and propose a customized test fixture that aligned precisely with the client’s signal measurement demand.

Allion’s engineering experts designed and delivered a tailored solution that provided precise, repeatable, and interference free measurements. This ensured that the client could accurately evaluate PCIe Gen 6 signal integrity and maintain compliance with upcoming standards.

The result was a fully customized test fixture that not only met the client’s stringent technical requirements but also enhanced their product development efficiency by reducing troubleshooting time and ensuring early compliance.

Implementation Benefits

Through this project, Allion demonstrated the value of expert consultation and precision engineering in addressing the complexities of next generation high-speed interfaces. The success of this collaboration reinforces the importance of early engagement and customized solutions for PCIe Gen 6 compliance in modern datacenter environments.

6 Key Advantages of Allion’s Customized Fixture Design Service

- Early technical consultation to define test needs and compliance goals

- Expertise in high-speed signal integrity and PCIe Gen 6 connector specifications

- Tailored fixture design that aligns with client-specific connector forms and electrical requirements

- Support for evolving test conditions, including de-embedding and total loss budget analysis

- Precision manufacturing to ensure consistent, repeatable, and interference-free measurements

- Rapid prototyping and validation to accelerate development timelines