Allion Labs

The three major requirements of server procurement quality correspond to three aspects: quality basis (specification requirements), user experience (performance requirements), and maintenance costs (stability requirements), explaining how the corporate procurement confirms and verifies its quality. In this article, we will discuss the stability requirement.

With the emergence of application services such as 5G, AI, cloud computing, and OTT (Over-the-top) streaming, these applications reflect that the server itself is a high-speed and high-capacity hardware foundation. High speed may be CPU calculating speed, GPU calculating speed, high-speed network transmission speed, or storage media access speed, and high capacity represents the memory capacity or storage media capacity. Due to the continuous generation of these high-speed application services, the power consumption of the server is also constantly increasing, from about 2KW power consumption in the past to more than 10KW power consumption for a single server today. The main problems derived from high speed and high power consumption are the thermal issues and the instability of speed. Therefore, the reliability test of temperature or temperature/humidity will be particularly emphasized in the stability requirements of the server.

The traditional server reliability test is carried out in a stand-alone manner. With the introduction of new application services and changes in concept, the server reliability test is now required from the application level, and the application level is different from the traditional stand-alone system. In addition to the highest and lowest operating temperature setting conditions for the reliability test, the biggest difference is the structure of the server group and the stress test software that executes the simulated application service. The server group at the application level of the architecture is usually built-in rack (rack) units (with multiple servers built-in), and the height of the rack is also from the early 42U to the current 48U or the newer 52U. The number also varies from one to three. When the above conditions of high power consumption and a number of racks are combined, there are very high threshold requirements for the Walk-in Chamber used for reliability testing. First, the chamber cooling power must be greater than the total heat generated by the entire rack server. Second, the internal space must fit the entire rack, and lastly, the load-carrying weight must be sufficient for the total weight of the entire rack server.

Allion collected the needs of different customers and built a large Walk-in Chamber that can meet the above requirements. First of all, its Heat-load capacity is 65KW, which can meet the total heat generated by most of the whole rack servers, the door height is 270cm, which can meet the entry and exit of 52U rack, the payload is 2000kg, and finally, the internal space can accommodate three racks to test together. In addition to the above specifications, Allion also provides three-phase or single-phase voltages ranging from 110V to 480V to meet various needs in response to different voltages around the world.

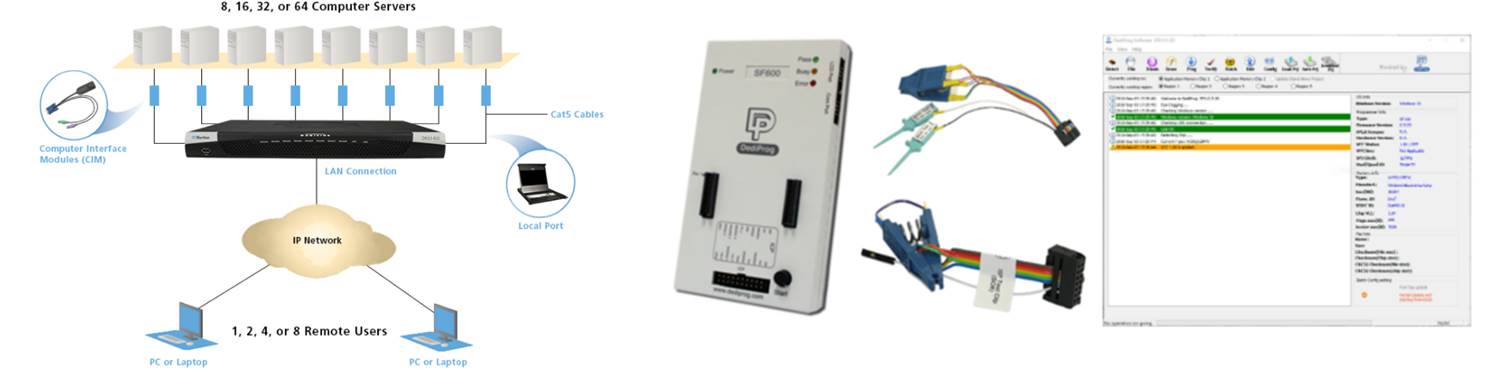

Allion has another advantage that traditional reliability laboratories do not have. Allion has an SIT (System Integration Test) team that can assist in the establishment of the entire server test environment, the execution of test software, monitoring the test status, and generating test reports. When there is a problem in the test that needs to be debugged, Allion can also assist in log file collection, remote access connection establishment, component replacement, software/firmware update, and even ROM BIOS flashing. The services of the above advantages can greatly reduce the probability of customers going to the on-site site or completing all the tests without going to the laboratory at all.

In addition to building a 65KW Walk-in Chamber, Allion also builds a wide-range temperature and humidity Walk-in Chamber to serve customers for some special needs of a single server. At the same time, in order to meet the spirit of one-stop service, Allion also purchased a Shock & Vibration machine to improve the reliability of service items to facilitate brand customers or cloud service providers in establishing QRS (Quality Requirement Standard) or When it is the Program of RFP (Request for Proposal), Allion has the capability to execute all test items.

If you have further needs, feel free to contact us through a contact form or email.