What is Acoustics?

Acoustics, or Electroacoustics to be more precise, is the science that deals with the reproduction and recording of sound through audio devices such as headphones, microphones, and speakers. Electroacoustics studies sound-electric conversion and the reception, storage, processing, transmission, measurement, playback, and application of sound signals.

It is not possible to discuss Electroacoustics without mentioning sound measurement. Usually, engineers measure sound with the Soundcheck software application. This is a set of audio or electro-acoustic test software developed by the Listen company and must be used in conjunction with a hardware system to provide a complete test environment. Soundcheck can be used to test virtually any audio or electroacoustic product, from stereos, earphones, microphones, telephones, to mobile phones.

Why do acoustics tests matter?

As consumers grow familiar with sound products, they have higher expectations for the products’ audio quality as well. Customers today expect more from their products than just being able to record and play back – top-notch audio quality is also a must. It is therefore not enough for factory inspectors to simply use their human ears to assess the sound quality of products, but rather to analyze and screen them through more professional acoustic tests.

What are the purposes of acoustics tests?

Acoustics testing ensures that a product meets end users’ expectations for sound quality – namely pleasant, undistorted sound during both recording and playback. Hence, acoustics testing enables factories to identify and fix defective products before shipping them to end-users.

What role does an acoustic engineer play?

Acoustic engineers play a pivotal role in ensuring that products are tested in a controlled environment and in accordance with specified requirements. If a product’s acoustics design is found to be poor, the factory will be asked to improve its process and incoming materials. Thus, acoustics testing can enhance product yield and reduce the chances for defective products to be shipped.

Professional services that Allion’s on-site/remote acoustic engineers offer our clients:

1) Consultancy and the establishment of a proper acoustics testing environment using the right equipment:

a) Our engineers will help clients construct a suitable testing chamber.

b) Based on product functions, use, and verification items, they provide consulting services for acoustics testing and assist in setting up the necessary testing environment. They will plan different verification items and acceptance levels depending on the products’ specific needs. For example, when testing a headset, the focus will be on noise/echo cancellation quality, whereas when testing a speaker, it could be on the frequency response curve and nonlinear distortion level.

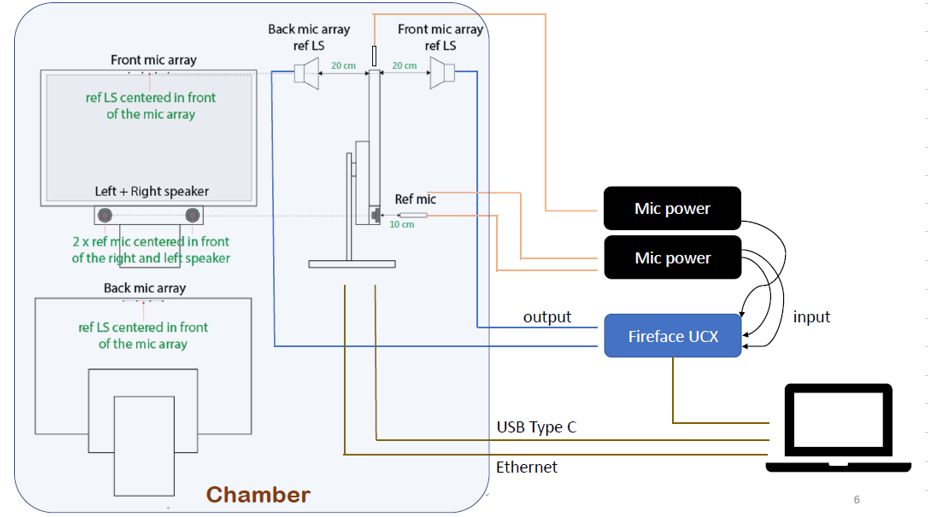

c) They will check the connection between the DUT and the recording/playback equipment and monitoring computer, confirm the operation method of the equipment and check the equipment list.

d) Diagram of the test environment setup

2) Adjustment and verification test of product and acoustic chamber:

a) By conducting environmental tests within the chamber, the engineers ensure the chamber being used is of good quality and operates ideally, which is essential for getting accurate and reliable results. Test results obtained from a properly constructed chamber are highly indicative of the product’s recording and playback quality, thereby providing strong proof as to whether or not the product lives up to consumer expectations.

Test items include:

- Loop test

This is an audio loop test that requires testing a product inside the chamber, which helps verify the input and output functions of an audio device and whether the sound quality is good. - GRR: Gage Repeatability and Reproducibility test

This test checks that the chamber’s internal environment is correct and that audio equipment and products are properly connected. It also checks sound transmission, namely the retraction and release between the DUT and the SUT. In this test, multiple operators use Soundcheck software to conduct the same acoustics measurements. Consistent and error-free results mean that the product is performing well. - Test of the audio equipment inside the chamber. This includes checking whether the Ref LS (Reference LoudSpeaker) is playing properly, whether the Ref MIC (Reference Microphone) is receiving sound, whether the sound insulation of the entire chamber is good, and whether external environmental noises will interfere with the test inside the chamber.

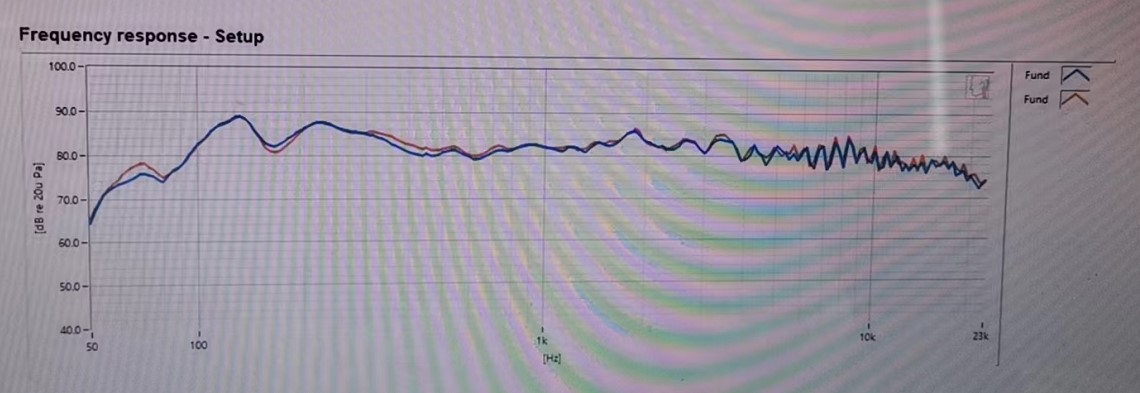

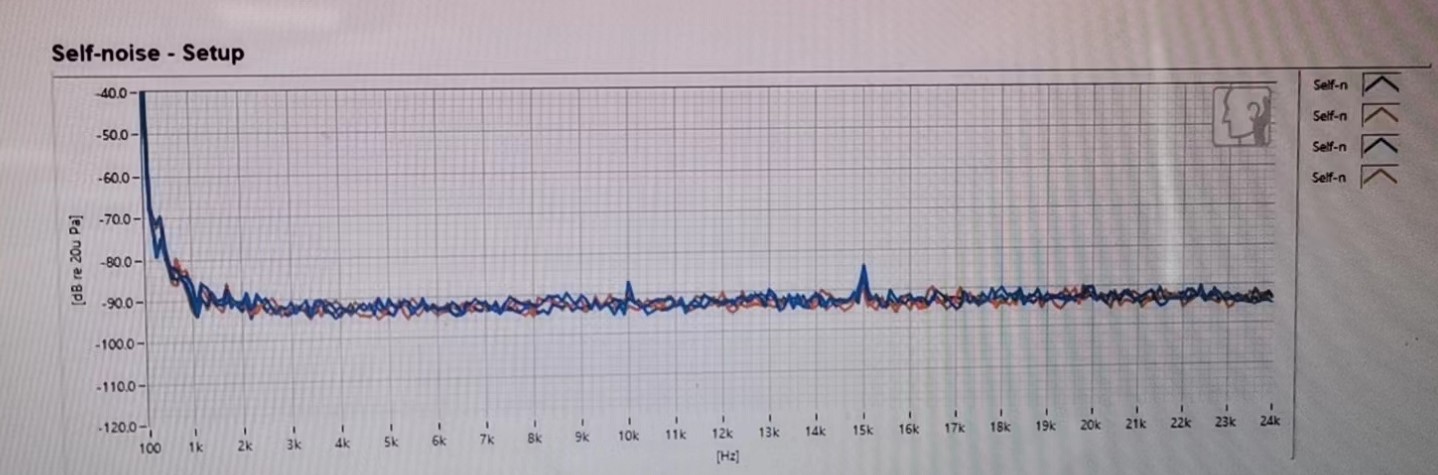

b) Environmental testing of products within the chamber. Our engineers determine whether the product meets customer demands based on the generated audio response/noise analysis curve (as shown in the screenshot below):

3) Follow-up, improvement, maintenance, and journaling of acoustic products’ quality:

a) Surface Mount Technology (SMT): From the mounting of the MIC to its transportation to the production line, follow up on any process that may lead to a defective microphone board.

b) Sub-Assembly: Check the assembly environment for the MIC board during subassembly, protect the interior of the MIC from contamination during assembly, and follow up on processes that may cause defective MICs.

c) System-Assembly: Follow up on any process that may cause defects when assembling the MIC board and speaker into a complete system.

d) Prepare an audit checklist to record the results of each process audit mentioned above. Audit the entire manufacturing process to confirm that each batch of products is of good quality. Processes can also be improved by optimizing audit checklists.

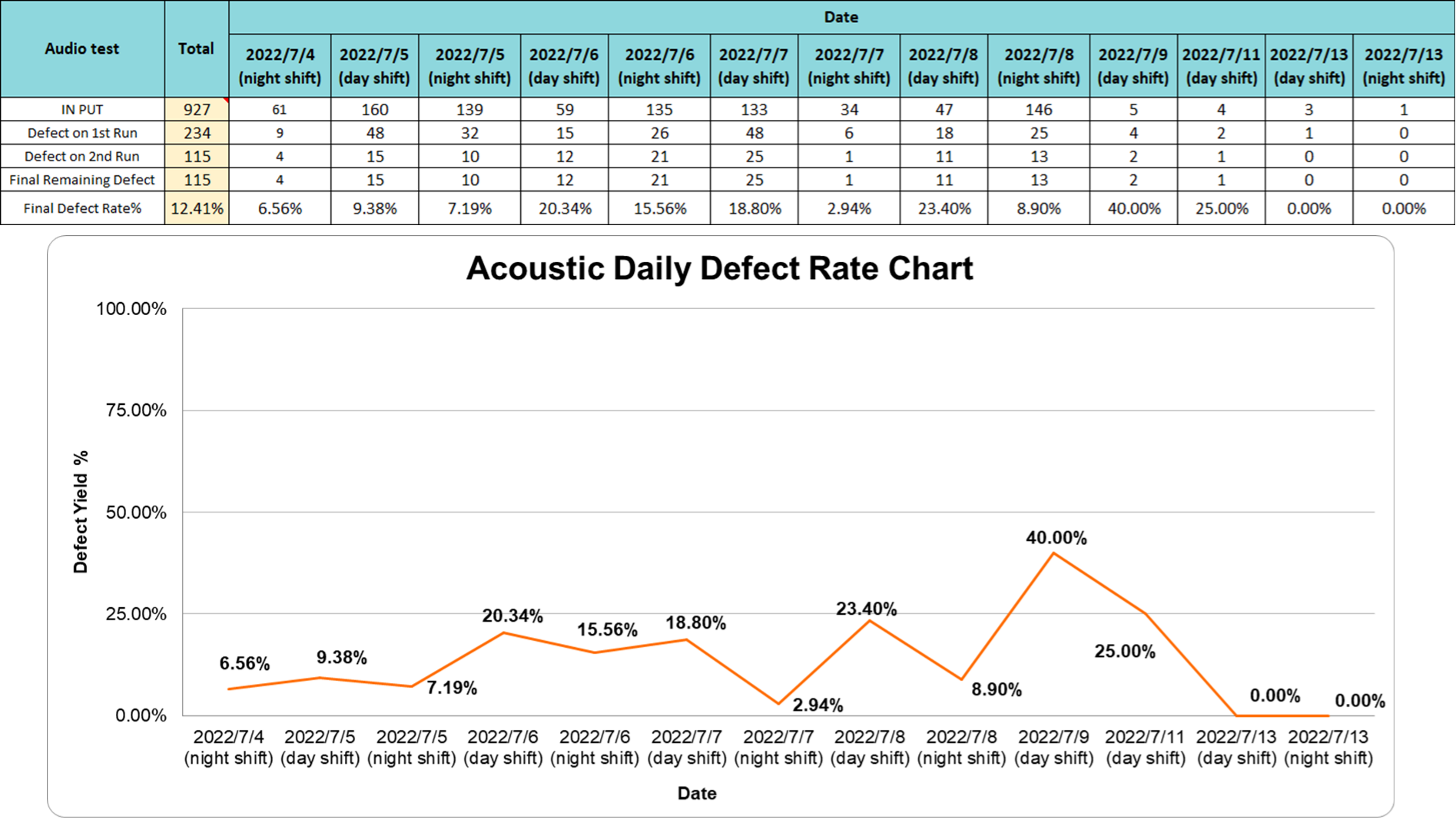

4) Statistics of product acoustics test yield

a) If the factory has statistics on the acoustic test results, we compare the factory’s statistical results with the on-site follow-up results to confirm whether they are consistent

b) If the factory does not have statistics on the acoustics test outcomes, we obtain the mass production data of previous batches and look at their acoustics test yield, then compare the current statistics with the previous batches.

c) Yield rate statistics table:

5) Failure analysis and troubleshooting of defects found in the product acoustics test:

a) We conduct failure analysis (FA) on the major issues found during the acoustics test, and either improve the process or improve the incoming materials as needed.

b) We make statistics on the maintenance results for the defective products screened out during acoustics testing, identify the problem, and fix it.

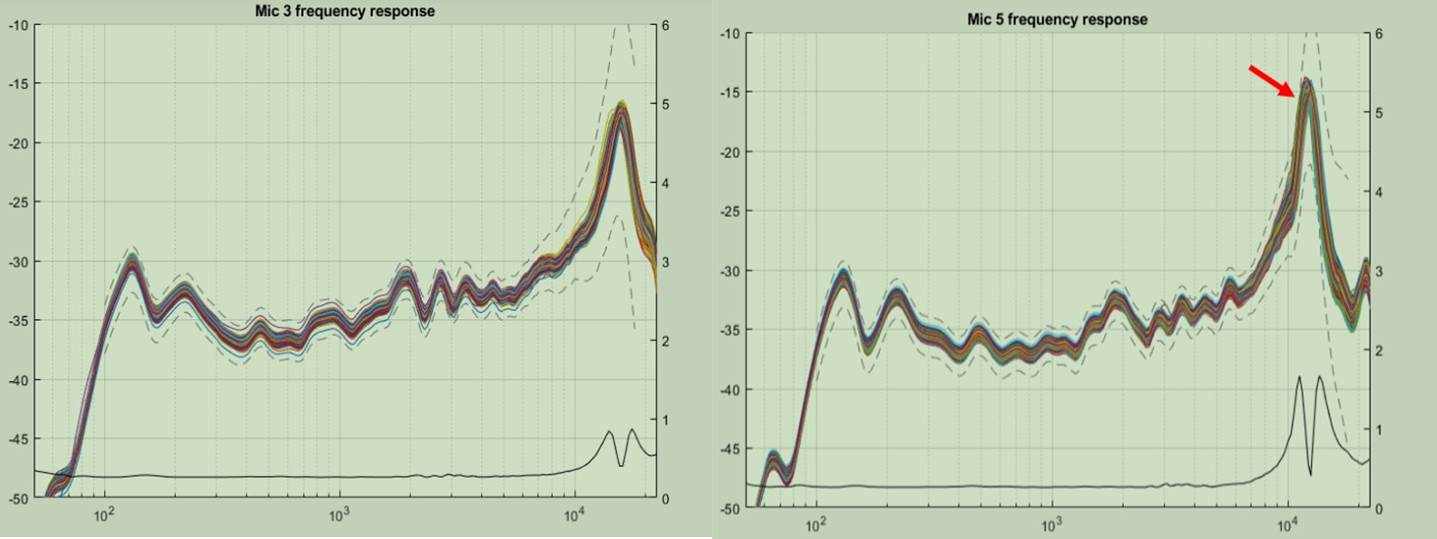

c) Using software tools, we review the log data from the product acoustics test, and compare the generated curves to identify, analyze, and resolve the underlying issues.

This is illustrated in the following two graphs, where a red arrow indicates an issue:

d) Allion can provide customized noise tests for customers and identify abnormal noise values for their products in specific bands, thus offering the basis for customer product improvement.

e) Allion continues to provide customized and standardized acoustics testing services for our world-class customers in the United States and Japan. Whenever a problem arises, our industry experts can identify the cause of the problem and offer solutions for improvement, thus assisting customers in verifying the sound quality of products and resolving problems at the design stage. This ensures high yield rates later on in the production process.

Take the Next Step

With over 30 years of IT testing experience, Allion Labs provides certification services, customized test services, professional market evaluations, and competitive product analysis reports for customers to improve product performance and user experience. Our company helps major manufacturers build brand reputations and take advantage of market opportunities in fierce product competition.

If you have any testing needs, please let us know by email or contact form.