Solid State Drive (SSD) has gradually become the focus for those who desire to enhance their storage equipment. Today, SSD's storage capacity has greatly improved; hence, with greater storage capacity “price” has now slumped to a more acceptable level for the consumer. After shaking off, the traditional conception of being over priced for casual and budget minded users. SSDs are now more efficient, cheaper, with greater storage capacity; compared with when they first hit the consumer market in the late 2000s.

Allion is deeply embedded in the DNA of storage product testing, at the same time an active member of the SSDA(Solid State Drive Alliance), whose members include ADATA Technology, ATP Electronics, Maxiotek and KingSpec (located in Shenzhen China).

The Migration to 2D TLC NAND

To kick off this inquiry of the four major trends in the second half of 2016 would be the adoption of 2D TLC NAND Flash for major players, due to its greater storage capacity. NAND FLASH has been the largest contributor to SSD material cost (BOM Cost); however, with the active adoption from SLC (Single Level Cell) or MLC (Multi-Level Cell) to TLC (Triple-Level Cell) with its larger byte storage, the rules of the game may have changed respectfully. This in turn benefits enthusiast multimedia users and heavy downloaders for the better good.

Yet, it’s not all sweets and goodies. Despite the many pros of this migration there are still some downsides. Respectfully

- TLC accommodates a relatively smaller number of write erase cycles in a specific block

- Compared to MLC it has a longer access time and longer latency

From a statistical stand point, in 2015 MLC NAND SSD sales accounted for 80-85% of total product sales in ADATA. Therefore the company estimates TLC NAND would possibly make up 70-75% of total sales in 2016 respectfully. Although the manufacturing of TLC SSDs would be more challenging, yet with the rigorous selection process of ADATA there would be no problem with its quality and competiveness.

3D NAND Big Boys Gear up for the Second half of 2016

Conventional Planar NAND are at this moment tip-toing on the edge of their respective physical limits; thus, they are no longer able improve in accordance with Moore’s Law. “But behold!” with the arrival of the latest 3D NAND technology the rule may have been bent for the better.

3D NAND can effectively stack package data; hence, greatly improving SSD density and cost issues. Technical Director Bill, Wang of KingSpec (located in Shenzhen China) points out: “Traditional planar 64GB NAND Flash chips, using 1Xnm MLC can be cut into 600 12-inch wafers, the use of 1Ynm MLC would produce 750, 1Ynm TLC 1000; The same is true with 3D, with 48 layer 3D process gradually being put into operation, the cost reduction will become increasingly evident.” With the start of the second half the year, both ADATA and KingSpec have launched their respective 3D SSD products; Maxiotek have also announced their newly developed control IC – MK8115, MK8113 and MK8215 to better facilitate and support the 3D-MLC and 3D-TLC NAND. When combined with “AgileECC” and “WriteBooster” (The former a security safeguard to greatly improve data error and correction. The latter a booster for SSDs to increase speed and performance) would fully cover the needs for consumer and industrial markets.

PCI-e/NVMe upgrades

PCI-e SATA Gen 3 has exceeded the maximum bandwidth limit, which has greatly improved in the read and write speed, if the capacity of a 6G PCI-E products, for example, SATA Gen 3 has a five times faster bandwidth, with a performance and continuous read and write speed of about 3 times, KingSpec Electronics Shenzhen and shared with us a PCI-e series, the series of products using LSI3008 master controller able to support PCI-e Gen3 X8 specifications, the maximum read and write speeds up to 4,000 MB / S, its largest capacities support up to 8 TB. Generally sufficient to meet consumer demand for storage, fast upload and download of digital content.

Demand Increases for Industrial and Commercial SSD Storage

With all eyes on Industrial 4.0, IoT and Big Data; information sources have become ever more diverse, at the same time refreshing at an alarming rate. Thus, the quest and attention for data authenticity have become paramount. There various distinctions between industrial and commercial storage devices (including hardware, drivers, software and validation), clients also require high levels of customization and premium reliability to cope with their demanding environments and challenges. ATP Electronics has over 25 years of experience in storage technology for application and compatibility related products, which include Industrial and Defensive industries that require uniqueness and reliability (For example IPC/JEDEC,IEC60529, ISO16949, MIL-STD.etc) respectfully. In order to conform to demanding industrial specifications for NAND FLASH,.ATP Electronics have further improved NAND FLASH on Unexpected Power Loss Protection patents. Enhancing and including memory stored on FLASH. Industrial grade SSDs products also require BOM management, this allows for better control and support of the product from 3-7 years respectfully.

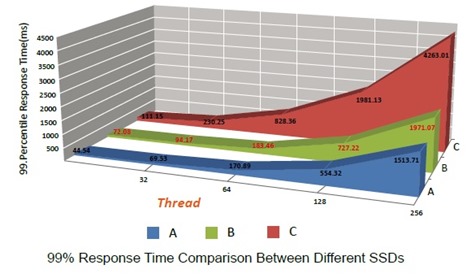

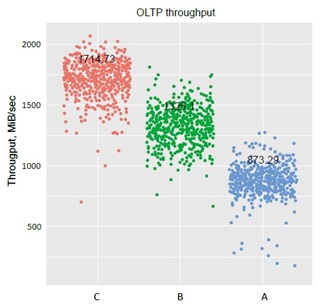

With Internet transactions becoming more frequently, the demand for business server platforms have risen, enterprise users want to be able to improve both existing server storage space, reduce user waiting time, reduce power consumption to saving cost. In the case of prolonged operation; ensuring the safety and reliability of the equipment,. at the same time paying attention to server hard disk stability and temperature adaptability will directly affect the error frequency and stability of servers. SSD product verification experts Allion; have coined the term and pioneered tailor made enterprise database application verification programs,. containing server compatibility tests for a large array of brands, enterprise application performance testing , big data framework verification and competitive analysis; especially focusing on Throughput, IOPs, Latency, Key performance, Energy consumption and performance analysis comparison.

Allion’s SSD Total Test Solution

Compliance Interface Conformance Test

Compliance Test programs include, but not limited to Thunderbolt/NVMe/SATA-IO.

Compatibility Test

Test with a wide range of test matrices including different:

• Product Type: PC, NB, Tablet …

• OS: Windows, Mac OS, Linux, Android

• Chipset

• RAID

A variety of list of equipment for various test requirements

Performance Test

- Long term, full range, dynamic performance evaluation

- Allion’s self-designed benchmark tool for delicate test case execution

- Pre-defined test workloads for user scenarios simulation

Data Integrity Test

- Long term stress test to validate SSD’s self-trim function and flush implementation

- Data conformance test to ensure no data is compromised due to possible defect/bug

Reliability Test

- Endurance Test

- Power Cycle Test

- Thermal Test

Power Consumption Test

Noise Interference

Scan

Several of hosts from different companies for interoperability test for NAND/Flash memories products