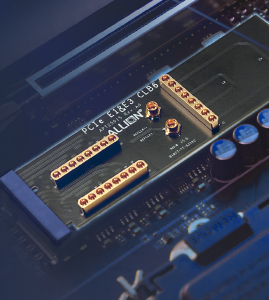

How Diverse AI Use Cases Make PCIe Gen6 a Critical Factor for System Stability

AI servers have entered an era defined by extreme computational throughput. From data centers and HPC environments to large-scale AI model training clusters, every AI server is now subjected to unprecedented demands — long-duration operation, sustained high workloads, and massive bandwidth requirements.

Behind these intensive workloads lies a critical yet often overlooked component that directly impact system stability: the PCIe interface.

As PCIe technology advances into the Gen6 era (64 GT/s, PAM4), system margins become increasingly fragile. Every signal path, connector, and insertion cycle can influence overall stability. Whether it is GPUs, CXL devices, SSDs, or NICs, unstable PCIe links can lead to bandwidth degradation, retransmissions, prolonged training time, or even complete system instability.

During product development and mass production, the very first gatekeeper of PCIe system quality is the validation quality of the test fixture.

Why Test Fixtures Become Even More Critical at PCIe Gen6 Speeds

With PCIe Gen6 adopting PAM4 signaling, signal integrity (SI) tolerances are dramatically reduced. A high quality test fixture is no longer a simple signal extension tool; it must satisfy multiple stringent requirements, including:

- Minimizing insertion loss

- Maintaining impedance consistency

- Controlling reflections and crosstalk within acceptable limits

- Ensuring measurement results truly reflect DUT performance—not fixture-induced artifacts

The quality of a test fixture determines whether engineers identify real issues or chase false problems. Inaccurate measurements do not only cause lab inefficiencies, they can magnify exponentially after a product enters the market.

Post-Launch Risks Caused by Poor Test Fixtures

Using real-world AI server cabling as an analogy, an unvalidated high-speed cable can lead to system-wide after-sales costs. Similarly, improperly designed PCIe test fixtures may expose enterprises to serious risks:

Risk 1: Misjudgment During R&D Leading to Mass Production Failures

Excessive IL/RL in fixtures can cause engineers to misinterpret DUT performance — either falsely identifying issues or overlooking real defects. Such problems often surface only after deployment, where the cost is significantly higher.

Risk 2: System Instability Driving Customer Complaints and RMA Costs

Minor PCIe signal distortion can result in intermittent GPU throttling, interrupted AI training, unstable long-term operation, and soaring RMA costs. In many cases, a single RMA can cost dozens of times more than the original fixture investment.

Risk 3: Project Delays and Missed Market Windows

Issues discovered after mass production often require product recalls, root cause analysis, re-validation, and redeployment, causing severe schedule delays. For AI server vendors, even a one-week delay may translate into millions in lost opportunities.

Risk 4: Brand Trust Erosion and Future Order Impact

Without SI-optimized fixtures, the entire PCIe validation process becomes unreliable. System stability is a cornerstone of server brand credibility. Once trust is lost, recovery is extremely difficult.

The Hidden Cost Savings and Tangible Benefits of High-Quality Test Fixtures

A qualified and reliable PCIe Gen6 / APEC test fixture is not merely about accurate measurement. A strategic upfront investment significantly reduces post-launch costs while delivering long-term stability benefits:

- Substantial reduction in RMA and repair costs

- Fewer customer complaints and stability-related issues

- Smoother data center deployment

- Shortened debugging cycles and faster project ramp-up

- Avoidance of rework, line stoppages, and production delays

- Higher project success rates in the AI server market

Allion Golden Methodology

Comprehensive Support for PCIe and APEC Test Fixtures

With decades of experience in high-speed signal validation, Allion integrates industry recognized standard fixtures with deep technical expertise through its proprietary Golden Methodology. This approach ensures every fixture meets optimal SI design standards and delivers stable, repeatable measurement results.

From R&D and engineering validation to stable mass-production solutions, and even customized APEC test requirements, Allion provides end-to-end support covering design, tuning, and measurement to help customers establish a solid foundation in high-speed validation.

Our Capabilities include:

- Mass production of standard PCIe Gen5 / Gen6 test fixtures

- Specialized APEC (Advanced PCIe Enclosure Compatible) fixture technology

- High-frequency SI simulation, routing design, and loss budget analysis

- Long-term collaboration with Keysight, Tektronix, R&S, and Anritsu

- Automated measurement scripts and complete validation workflows

Time to Market with Quality: Allion Paving the Way to Success for Your Products

In the high-speed AI server era, enterprises need more than high-performance hardware. They need reliable foundational test capabilities. A precise and dependable PCIe Gen6 test fixture reveals real issues early, preventing misjudgment-driven customer complaints and maintenance costs, while ensuring stable AI server quality and on-time market delivery.

If you face challenges during product development, testing, or certification, please feel free to contact us through the online form. Allion is ready to provide customized solutions to help your product stand out in today’s competitive market.