In the field of industrial automation and smart manufacturing, the stability and reliability of industrial controllers have never been just performance metrics. They are directly tied to production line safety, equipment uptime, and operational efficiency. For industrial systems operating in harsh environments, any latent instability—if left unaddressed—can quickly escalate into substantial maintenance costs and operational risks once products enter mass production or field deployment.

The Urgent Need to Solve Signal Integrity and Hardware Stability Issues

In this article, we share the experience of a leading domestic industrial control manufacturer that has long specialized in high-end industrial control and precision automation. Its products are widely deployed in CNC equipment, smart manufacturing, and mission-critical industrial systems.

As DDR, eMMC, and high-speed Ethernet are introduced into next-generation controllers, system performance improve significantly. At the same time, however, these upgrades introduce new challenges related to high-speed signal integrity (SI) and hardware design stability.

Unlike conventional service providers that focus solely on SI measurements, Allion adopted a consulting-based approach in this project—combining dedicated interposer measurements with in-depth Hardware Review. This enabled the customer to move beyond raw measurement data and achieve tangible optimization of high-speed interface designs.

New Challenges in High-Speed Design for Industrial-Grade Applications

The industrial controller in this case was required to operate continuously under conditions of high temperature, strong vibration, and significant electromagnetic interference. As a result, the system demanded high fault tolerance and long-term stability.

However, with the increasing data rates of DDR, eMMC, and Ethernet interfaces, relying solely on past design experience was no longer sufficient to fully understand how high-speed signals behaved in real system environments.

The customer sought an experienced third-party technical team that could not only perform SI measurements, but also deliver practical, actionable design improvement recommendations based on those results—serving as a critical reference for future product iterations and design decisions.

Beyond Measurement: The Real Enemy is ‘How to Improve’

During development, the customer’s key challenge was not whether to perform SI measurements, but rather the lack of clear improvement paths afterward. Specific issues included:

- DDR and eMMC eye margins measured on the actual board were approaching specification limits

- Custom connectors and complex routing topologies significantly increased the risks of signal reflection and crosstalk

- Limited in-house measurement equipment and test environments, along with insufficient capability to systematically map measurement results back to circuit and PCB design decisions

In many cases, even when SI issues are successfully identified through measurement, they cannot be effectively resolved in the next design revision without correlating them to routing topology, stack-up design, or grounding strategy.

Interposer Measurements & In-Depth Hardware Review

Creating a Complete Design Improvement Cycle

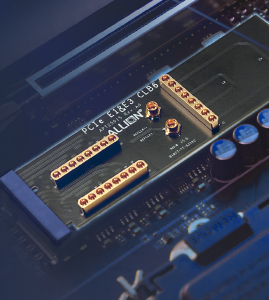

1. Interposer Measurement Solutions for DDR / eMMC

Allion developed DDR and eMMC interposers as the core measurement tools for this project, ensuring that results accurately reflected real system behavior:

- Precise impedance control to minimize fixture-induced measurement distortion

- Direct integration into the actual system architecture for realistic operating conditions

- Use of advanced measurement equipment to perform eye diagram, timing, jitter, and reflection analysis

- Fixture fabrication and integration support to lower the barrier for customer adoption

2. Hardware Review: From Measurement Data to Circuit and Layout Analysis

After completing SI measurements for DDR, eMMC, and Ethernet, the customer further commissioned a Hardware Review on real measurement results. This involved an in-depth examination of circuit architecture and PCB layout to ensure sufficient stability and design margin under high-speed operation.

DDR / eMMC Circuit and Layout Review

- Specification Check: Verification of compliance with relevant interface standards

- Trace Length: Review of routing length and length matching to prevent timing skew

- Signal Bandwidth: Evaluation of whether bandwidth meets real operating requirements

- Layout: Examination of routing topology, stack-up structure, and return path integrity

Long-term operational risks were also assessed, including:

- Whether connector bandwidth could become a bottleneck in high-speed channels

- Whether routing from DDR / eMMC to connectors introduced reflections or impedance discontinuities

Ethernet Circuit and Layout Review

- Ethernet Trace Path: Ensuring continuity and minimization of signal paths

- Trace Length: Verification of differential pair length matching

- Signal Bandwidth: Assessment of channel bandwidth for high-speed Ethernet operation

- Layout: Review of differential spacing, layer transitions, and grounding design

Further optimization recommendations addressed potential bottlenecks such as:

- Connector bandwidth limiting overall channel performance

- Signal degradation caused by routing transitions or layer changes

Through this Hardware Review process, SI observed during measurement were not only documented but directly mapped to real circuit and layout structures. Concrete, actionable design modification recommendations were then provided, giving the customer a clear direction for the next design revision and significantly reducing the risks of repeated board spins and extended debugging cycles.

Mastering Industrial-Grade High-Speed Design: From Validation to Complete Design Optimization

By implementing a complete closed-loop workflow—

Interposer Precision Measurement → Data Analysis → Hardware Review → Design Improvement Recommendations—customers gain:

- Measurement and analysis results that directly support design decision-making

- Early elimination of potential SI risks before pilot production, reducing repeated PCB spin costs

- Significantly improved long-term stability of industrial controllers operating in demanding environments

Ultimately, this approach not only ensures product quality but also reinforces the customer’s technological leadership in the industrial control market.

Beyond Identifying Problems—Enabling Real Improvement

We firmly believe that true SI consulting services go beyond pointing out what is wrong—they must also guide how to improve. Moving forward, Allion will continue to combine advanced measurement capabilities with deep Hardware Review expertise, serving as a trusted long-term technical partner in the field of industrial-grade high-speed hardware design.