Allion Labs

Is your cable ready for an endless tug of war?

Have you ever suffered from unsuccessful power charging with your aging USB cable? Did you know that this might be a warning from your USB cable?

Since most people don’t know, we would like to share some crucial points about cable materials. There are countless types of USB wires on the market. As the wires are fully wrapped in the product, a cable’s durability directly affects its lifespan and safety. Contrary to popular belief, you cannot determine how long it can be used only based on the cable’s appearance.

Starting with its structure, a USB cable is composed of several wires, with the USB 3.0 cable containing dozens of wires. Each time cables are used, the cables and connectors wear out a little more. If the material is not strong enough, it affects the product’s lifespan, transmission, or charging efficiency. This is why the USB-IF has set rigorous test specifications to ensure a certain useful life and decent transmission quality of all USB cables.

From supporting 10W at first and reaching 240W power in the latest versions, USB specifications have come a long way. More devices are now charged with USB cables, including mobile phones, tablets, laptops, and even larger LCD monitors and LCD TVs. Bearing the critical task of power charging, some wires are specialized in power transmission in the USB cable, which makes the healthiness and durability of such wires a bigger concern. The durability and the usage scenario of the user are highly correlated.

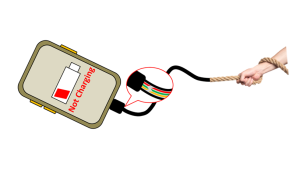

As a heavy user of USB cables, have you ever pulled to unplug the USB cable in a hurry, for convenience, or due to an unintentional habit? When the product is not robust enough, you may tear some wires without noticing it due to the unchanged appearance of the cable. If you tear the wire for data transmission, the transmission process will become slower or ever interrupted under this circumstance. After tearing the wire for power transmission, it may cause charging abnormalities or inability to charge in relatively minor cases or even lead to dangers like the cable melting or burning.

Such accidents are often seen in news reports and customer complaints on e-commerce platforms, but how can the problems and risks be prevented? This is where the product’s useful life test comes in.

Allion Labs creates user behavioral simulation tests tailored for our clients. To ensure that the structural strength of the cables and processed parts can survive under different pulling scenarios while maintaining quality and charging safety, we can design tests targeting the cable’s useful life and safety under different usage scenarios that reflect users’ actions. The pull-out test examines the product strength of the cables and the junctions of the connector, to ensure that a certain number of uses within a certain period won’t cause the aforementioned problems.

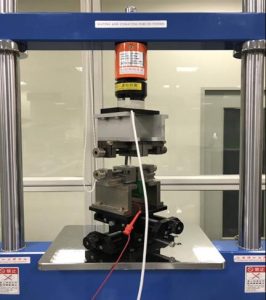

Figure 1: Pull-out test setup

Figure 2: Simulate user actions by pull-out test

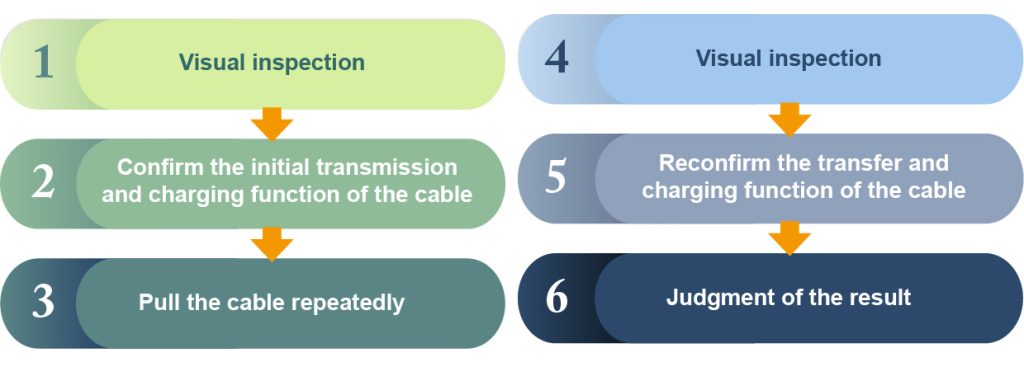

Allion Labs designed three types of useful life testing scenarios: light user, heavy user, and customization. Take the light user scenario as an example, the average demand for charging is once to twice daily, thus every 750 pull-out cycles can be determined as one year of useful life. The product’s transmission and charging functions are tested before and after the repeated pull-out tests to ensure that the product can function properly within the one-year warranty period. As for heavy users, the number of the test cycle is increased.

Table1: Test process

Allion Labs possess the most comprehensive test equipment and experience for the cable/connector industry. We design exclusive test planning based on the customer’s needs and help them to select the better products and suppliers, reducing after-sales costs and customer complaints. Have questions about any product or testing? You are always welcomed at Allion Labs.

Take the Next Step

Allion Labs has accumulated years of verification experience in cable connector products. Our service covers all the way from product design and acquisition of certificates to production management. We will always support manufacturers in their ventures.