As technology advances, more and more types of portable electronic devices have surfaced. Due to the limitations of current technology, the sizes of electronic products have stopped decreasing. The trend has now become being able to fit more functions into a fixed size.

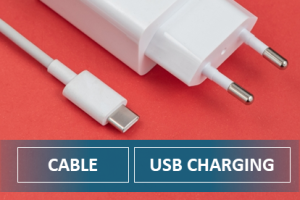

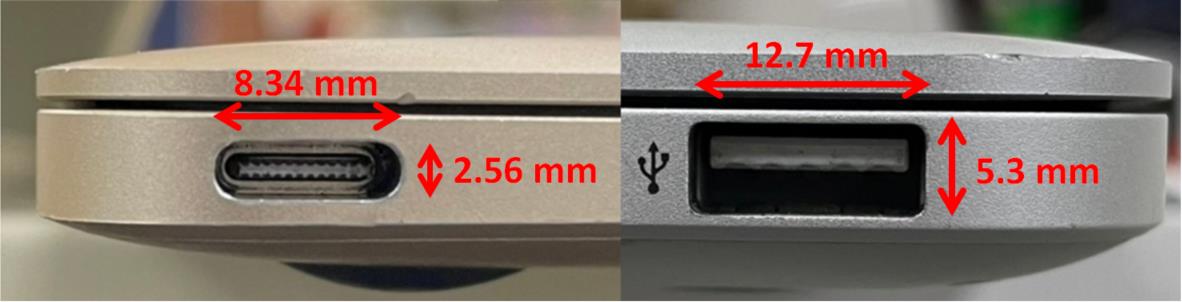

In the early days of portable products, larger I/O ports were used. As the sizes of the products became smaller, the interface also needed to be smaller. For example, the mainstream USB interface of a laptop used to be the USB Type-A connector (on the right of the figure below), now it has changed to a USB Type-C connector (on the left of the figure below).

The smaller size and faster transmission speeds of the USB Type-C connector are what made it the mainstream port interface. However, the smaller size makes it less force-resistant.

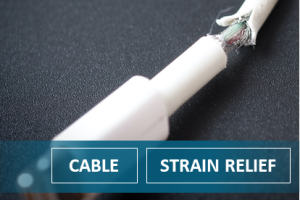

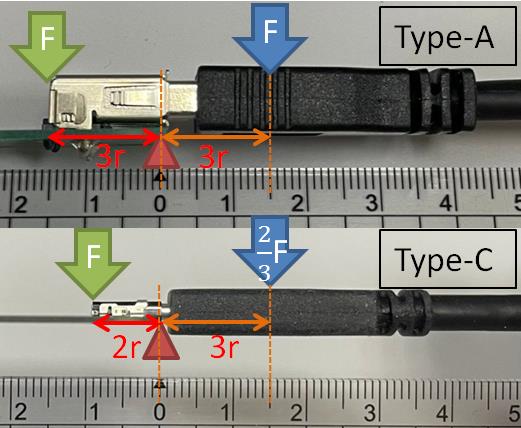

In the figure below, the green arrows show the maximum force for pulling the Type-A and Type-C connectors off the PCB board. Using the port as the fulcrum (red triangle), we can calculate the torque for each position on the cable using basic physics. If a force value of F is applied to the right of the Type-A connector’s fulcrum, the connector will detach. As for the Type-C connector, it can only withstand a value of 2/3F. So as connectors become smaller in size, their resistance to force also decreases. This means that increasing the strength and durability of smaller connectors like USB Type-C will require more thought and attention.

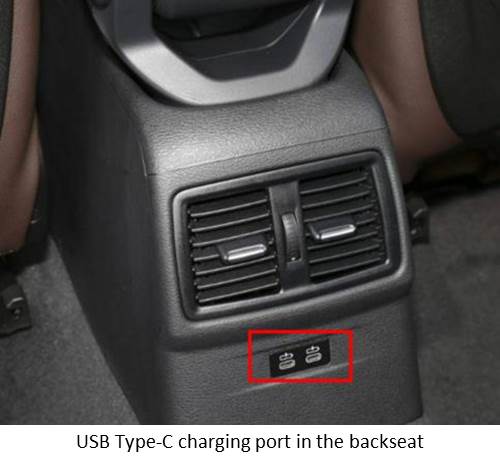

As USB Type-C is becoming more popular, charging ports in automobiles are also adopting these types of interfaces. Has the following situation ever happened to you?

Passengers in the back seat of a car are using a USB Type-C cable to charge their phones. Suddenly, a passenger in the back seat accidentally kicks the charging cable when changing seats, putting too much force on the cable. As a result, the charging port was damaged, causing the connector port to fall out and unable to charge devices. To fix this, the vehicle must be sent to the original factory for repair. The whole process becomes very time-consuming and expensive.

To deal with the issues mentioned above, directional force strength testing can be used to test the strength of ports, verifying if they meet the standards that prevent damage. Taking care of this can prevent external forces from damaging charging or data transmission functions that require replacing the entire motherboard.

Allion is a certified laboratory that has partnered with many international associations. We have decades of work experience with connector specifications and verifications, allowing us to provide the following consulting services:

1. Connector Selection: Allion is familiar with various specifications and certifications of different connectors from different manufacturers. We can provide the best manufacturer recommendations for our clients, based on their needs.

2. Design Suggestions: Allion can help notify clients of potential risks, important considerations, and most importantly their countermeasures during product design. Using the example mentioned above, Allion can help clients confirm whether the strength of the welding and outer casing of the backseat charging port is up to standards.

3. Design Verification: Allion has complete testing laboratories, testing environments, and testing equipment to verify the potential risks for our clients, ensuring the probability of them happening is minimized.

Through above testing services, Allion can provide a faster, easier and better integrated consulting services and solutions. No matter the phase of the product, Allion can assist clients in boosting product quality, optimizing production efficiency.

Faster, Easier, Better: The Most Trusted Testing Consultant

With its advanced high-frequency and high-speed measurement capabilities and more than 30 years of hands-on experience, Allion is ready to provide comprehensive customized technical support to customers of cable connector-related products. No matter the phase of the product, Allion can assist clients in boosting product quality, optimizing production efficiency, and delivering faster, easier, and better integration consultation services and total solutions.

Faster

With industry-leading high-frequency and high-speed measuring capabilities, no matter what the product stage is, Allion is able to help our clients to further accelerate the product testing cycle for various standard or special specifications.

Easier

By implementing AI and automation solutions, Allion ensures that every test is “qualitative, quantitative, and reproducible”, helping our clients to improve product performance in a more efficient manner.

Better

With more than 30 years of expertise, specialized technical team, and comprehensive testing environments and equipment, Allion is committed to providing clients with more improved quality of service based on extensive experience of User Scenario Testing.

If you have any further needs for testing, verification, or consulting services, please feel free to contact us through the online form.