Cables are what connect signal sources to the monitors. The longer the cable, the higher the signal attenuation is. Modern cables that support 8K/10K resolutions have faster signal transmission speeds but have higher signal attenuation. Using a chip to optimize signal quality can be a great way to maintain cable length. These cables are called active cables. The quality of this kind of cable can be determined by the PCB board on the chip with impedance being one of the most important factors to consider.

Potential Risks That Impedance Brings to the Table

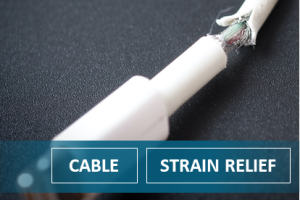

When impedance is poorly controlled, signal attenuation, return loss, and crosstalk can occur. These can cause users to experience screen flickering and sometimes it can even cause there to be no signal. If this happens during an important meeting or occasion, it can cause great inconvenience.

Many factors can potentially affect impedance. Some considerations should be made during product design, material selection, and even manufacturing. Only after considering these steps can the impedance be controlled to a desired range. Below are some of the possible factors that can affect impedance.

Routing Width and Thickness: The impedance will be smaller if the routing width or thickness is larger. Standard board manufacturers will generally control the tolerance at 10%. It’s hard to find one that can do it at 5%.

Material Thickness: The material thickness of different boards and how they’re made can also affect impedance. The thickness of the base and the lamination is hard for board manufacturers to control.

Solder Mask Thickness: Applying a solder mask can also affect impedance. Sloppy painting and different colors of paint can greatly affect the results.

Some active cable manufacturers use low-priced materials that are not in compliance with rules and regulations due to cost. Because of these manufacturer’s lack of understanding, they are unable to evaluate and verify these products. These actions will inevitably lead to negative user experiences.

Allion used a failed HDMI active cable for testing. When the impedance drops below the recommended range, issues can start to occur.

Faster, Easier, Better! Allion’s Product Verification Solutions

Allion has a complete range of testing equipment, resources, and decades of testing experience to provide clients with consulting services regarding active cables. In addition to providing customized solutions, we also have the following advantages:

Faster

Allion has rich development experience and testing fixture development capabilities to assist international associations in designing the test fixtures. We can help our clients to customize their test fixtures for their products more quickly and accurately.

Easier

Allion has a complete range of testing equipment, analysis software, and testing fixture development capabilities. We regularly purchase new products on the market for research to assist clients in formulating customized testing plans and building customized test fixtures. Partner with us to improve your products without wasting time and money.

Better

Allion has the most consultants and the highest quality service in the industry, allowing clients to spend a low amount of money for a strong, experienced, and resourceful team with a complete range of testing equipment that can help them solve issues efficiently.

If you have any further needs for testing, verification, or consulting services, please feel free to contact us through the online form.

Contact Us