Make Durable USB Cables With the Insertion and Extraction Test

Mobile phones are always with us. For work, entertainment, or tasks for daily life, our mobile phones allow us to do many things we couldn’t do before. Market demands for charging and consumer expectations are growing exponentially. Although wireless charging is evolving, its charging efficiency is still lower than wired charging. In addition to this, USB cables also allow for data transmission, making them the most important accessory for mobile devices.

What’s Causing USB Cables to Break After a Few Charges?

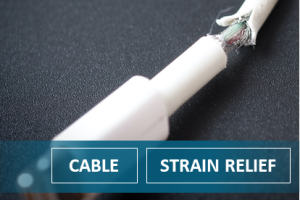

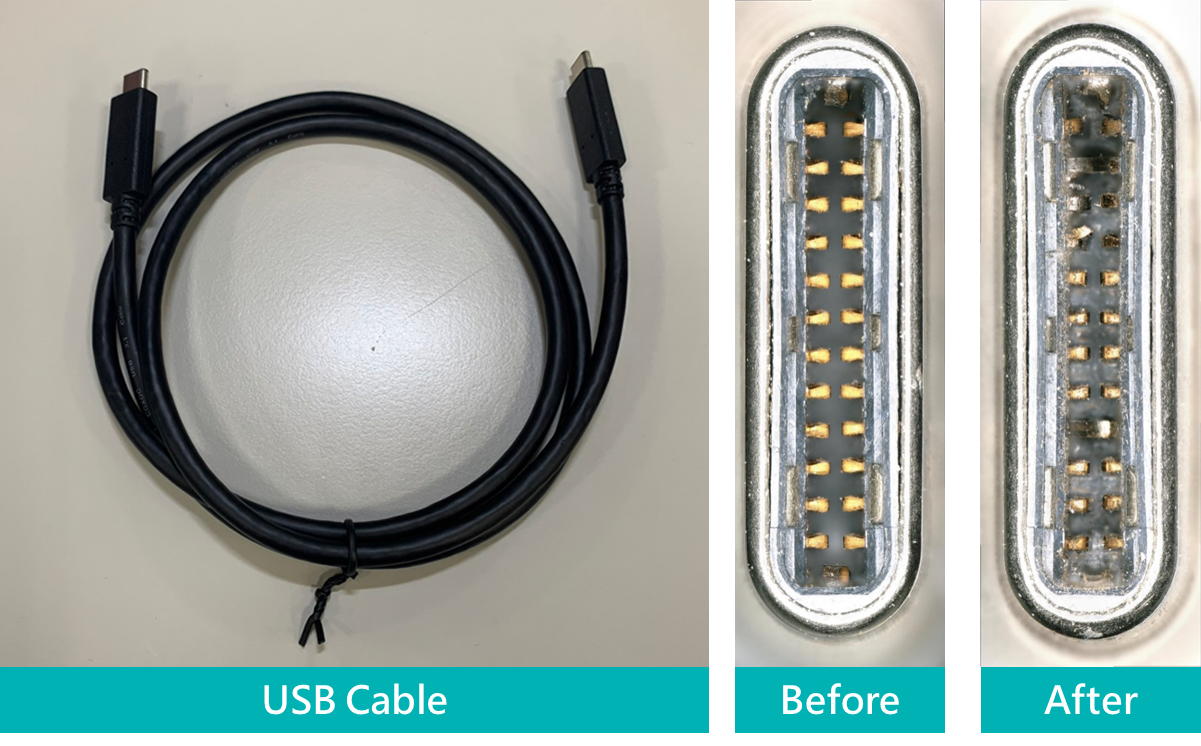

USB cables have been widely used for mobile devices and PC products. Cables are considered to be consumables since they will need to be replaced after long-term usage. As long as they are used normally, they can have a basic product life of a few years. Based on our decades of testing experience and a large collection of consumer feedback from the Internet, we found that what is most unacceptable for users is a cable being used for less than a month or even less than 10 times, and it stops working. After exploring further into this issue, the most common reason for this is due to the connector end of these cables gets damaged from plugging and unplugging.

Insertion and Extraction Test: Simulating User Scenarios

To solve these issues, Allion’s professional insertion and extraction test can be conducted for verification. Users will probably encounter various physical feelings when using USB charging cables. If the insertion/extraction force needed is too small, it will make users think the cable easily loosens or the charging connection is easily affected. As a result, users will try to insert the cable with excessive force. On the other hand, if the connector is too tight, it will also cause the user to use excessive force to plug in or out, causing damage to the wiring or causing damage to other parts of the cable. These two situations could even potentially cause damage to the mobile device that’s connected. If an expensive device is damaged because of a charging cable, who’s going to pay for the damages?

Faster, Easier, Better: The Most Trusted Cable Validation Testing Consulting Service

As a professional testing and consulting lab, Allion can assist USB cable manufacturers in obtaining USB certifications, conducting product verifications, and performing customized experiments and tests according to our client’s needs. We can provide improvements and suggestions for clients no matter which phase of product development they are in. Our services cover product design, quality testing, product verification, and more, applying the requirements of various associations to the testing at the same time.

- Compatibility Test and Functionality Test

- User Experience Test

- High-frequency Signal Measurement

- Stability Test

- Competitive Analysis and Consulting

Faster

Allion’s professional team utilizes decades of testing experience, experts in technical fields, and an accumulated database from over the years to provide fast solutions for our clients regarding the development and design of USB cables. We can also provide clients with consulting services related to technology, safety, compatibility, regulations, and more, ensuring product quality for our partners.

- Quickly provide product development certification strategies with rich testing experience and collection of testing equipment

- Quickly obtain logo certification (USB)

Easier

Allion’s team has an in-depth understanding of cable products, a complete range of professional skills, and years of high-frequency product testing experience. This allows us to identify issues during the testing process quickly and provide our clients with the correct solutions. With our testing solutions, we can ensure each client’s certification process is qualitative, quantitative, and reproducible. Through Allion’s professional issue isolation and debugging support, we can assist our clients in obtaining accurate test results easily, ensuring the quality and performance of their products.

- Provides more accurate results

- Provides professional issue isolation and debugging support for our clients to make product development more convenient.

Better

As a partner of distributors and manufacturers, we provide comprehensive services and relevant applications during the product design phase. We can introduce correct concepts that conform to the rules and regulations of various associations and implement strict product verification and testing before and during mass production. Allion can help distributors and brands ensure the reliability and compatibility of their products so consumers can use their products safely.

- Assist clients in establishing supplier management and conducting quality control for mass production.

- Conduct user scenario testing to explore potential risks and issues

If you have any further needs for testing, verification, or consulting services related to the cables and connectors, please feel free to explore the following services online or contact us through the online form.