Vibration Stress: The Invisible Danger

As mobile devices are more popular than ever, many electronic devices are no longer used for specific situations and environments. When using products in different locations, you will inevitably encounter environmental Stress. From our research, we found that consumers have reported abnormalities when using their electronic devices, and some people’s products were damaged during transport. It was found later on that a large part of the damages were due to vibrations. Now, product structure and product packaging have become a serious issue of discussion for electronic products, as well as how these products are shipped.

How to Assess Vibration Stress in Different User Scenarios

If electronic products malfunction because of vibration, users will not have a good experience with them. This can affect the consumer’s willingness to purchase and can also lead to extra costs like warranties.

Allion, a professional testing laboratory, has the advantage of a System Integration Test (SIT) team. We can integrate user scenario simulations with other types of product tests and get more accurate test results. Below are some of the common causes of vibrations.

» External force: External force or machinery is one of the most common causes of vibrations. For example, mechanical equipment, transportation, earthquakes, airflow, and others. As long as vibrations are generated, there is a risk of damaging the products.

» Vibration resonance: When an external object’s vibration frequency is close to the natural frequency of another object, vibration resonance may occur. This causes an increase in the product’s vibration amplitude, which could lead to component damage.

» Mechanical failure: Failure, natural wear, or incorrect installation of components could cause vibrations that lead to more failure. This causes components to malfunction, along with the product.

» Electronic vibration: Changes in current and voltage within electronic components and circuits could also cause vibrations. This type of vibration usually has a very high frequency.

» Friction: Friction can cause an object to vibrate, especially when the object is sliding across a surface. This type of vibration is called sliding vibration.

During our user scenario verification test, we simulate the environmental conditions and consider the product is in during different usage scenarios. We also simulate the operating behaviors of different users. From experience, we’ve discovered the following common issues.

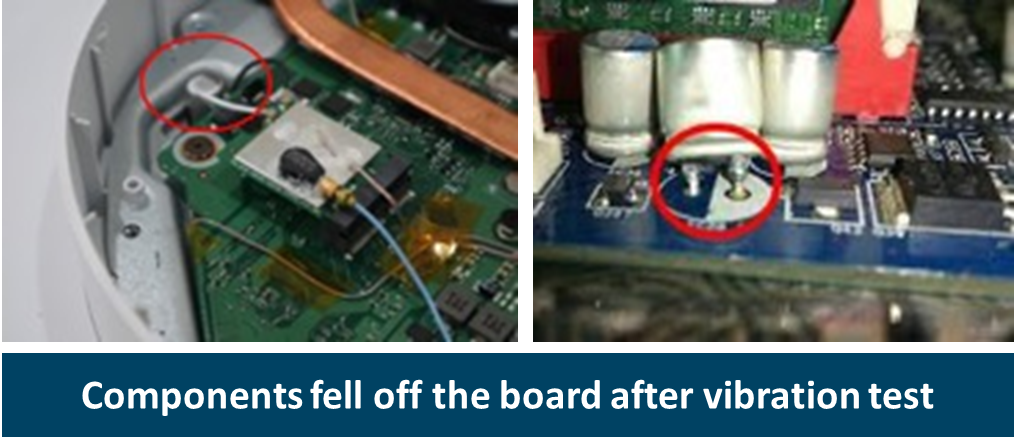

- When a connector or component undergoes vibration testing simulating different shipping methods and a soldering point breaks or detaches, it means the design of the soldering points or the assembly is not good enough.

- After the vibration test involving consumer use, some functions of the product malfunctioned, meaning that some module functions and mechanisms were poorly designed.

- After performing a test involving transportation simulations, the contents were scratched, indicating that the packaging was poorly designed and the product inside was not protected well enough.

Uncover Hidden Risks with Realistic User Scenarios

To find out hidden potential issues with a product, user scenarios are a crucial part of the process. Allion can provide clients with technical consulting services with user scenario testing. With these simulations, we can deeply explore the potential issues of these electronic products. Allion can help clients understand the reasons behind the issues and improve the product to meet users’ needs.

With our testing services, customers can expect the following support:

Quality Control and Validation

Vibration testing can ensure the product quality will meet market standards and specifications. By conducting these user scenario tests, performance and reliability can be guaranteed.

Durability Evaluation

Vibration testing can simulate situations such as long-term vibration exposure, effectively evaluating the product’s durability levels.

Performance Evaluation

The performance of products could be affected by vibrations, for example, components can be damaged. Running a vibration test can help us determine how well an electronic product can perform under various vibration conditions. This is to ensure the products can meet their expected requirements and standards.

Product Development

During product design, vibration testing can help designers and engineers evaluate and compare the effects of different designs, such as materials. This tremendously helps designers make better decisions and detect potential issues early..

Faster, Easier, Better: Allion User Reliability Test & Consulting Service

As high-frequency and high-speed product applications continue to evolve, relying on traditional reliability testing is no longer enough. That’s where Allion Labs comes in. We understand the critical role that user scenarios play in revealing potential risks. With our vast expertise in user scenario testing, Allion can provide our clients with professional and in-depth user scenario verification consulting services.

Faster

Allion can provide industry-leading product testing which includes evaluations of high temperatures, low temperatures, and degree of vibration. Specification suggestions, supplier selection, and sample specifications are also a part of our services. It doesn’t matter which stage your products are in now, we can provide our clients with services that correspond to various standards and specifications, speeding up the product testing phase.

Easier

Allion has more than three decades of professional experience, professional technical teams, and a complete range of testing laboratories and equipment. Once potential product-related risks are detected, Allion can assist customers in clarifying the possible causes of issues, providing debugging support, and suggesting solutions. This helps enhance product quality and overall performance more easily.

Better

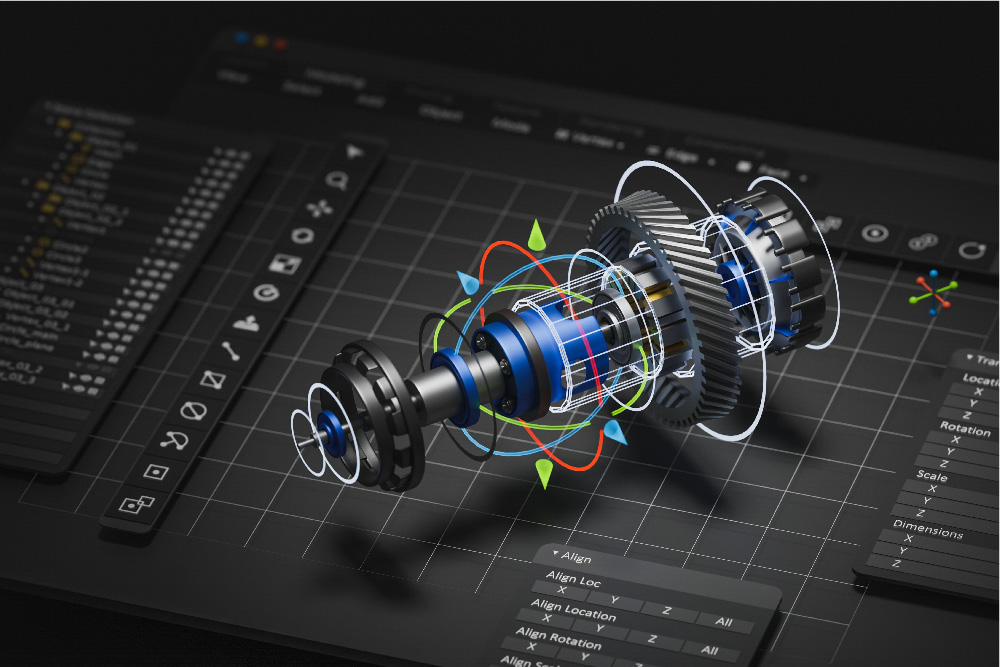

At Allion Labs, we excel in System Integration Testing (SIT) to ensure the success of your projects. With our expertise, we can simulate real-world scenarios, set up product load conditions, and replicate user interactions. In case any issues arise by testing, our SIT team is ready to assist with troubleshooting, log file analysis, component replacements, and software/firmware updates. We are even assisting with ROM/BIOS flashing.

With our comprehensive services, you can minimize the need for on-site visits and complete all testing seamlessly. Partner with Allion Labs for hassle-free and outstanding project outcomes.

If you have any further needs for testing, verification, or consulting services, please feel free to explore the following services online or contact us through the online form.