Product Traceability IIoT Platform

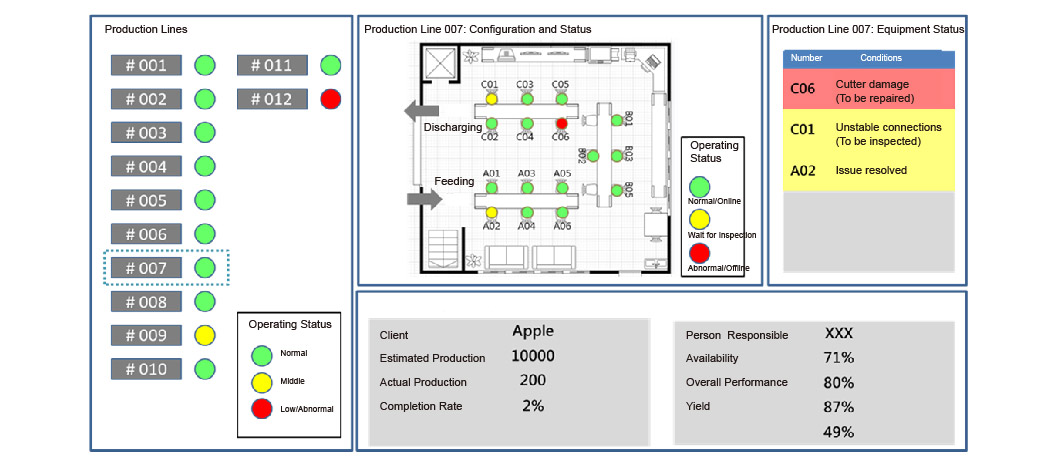

Allion’s Product Traceability IIoT Platform is a fully connected and flexible cloud system designed to detect abnormalities on tools and collecting real-time production data.

The Smart Factory Solution that Ensures Responsive, Adaptive Cable & Connector Manufacturing

Industry 4.0 revolutionizes the way cables and connectors are designed, manufactured, and tested. In the relentless pursuit of quality and efficiency, vendors now need to take a leap forward from more traditional manufacturing lines to an agile, digitalized smart factory.

Allion’s Product Traceability IIoT Platform is a fully connected and flexible cloud system designed for those who want to embrace smart manufacturing. The cloud-based platform offers a comprehensive, turnkey service from detecting abnormalities on tools to collecting real-time production data. Along with the seamless integration of machine vision, robotic arms, and sensors, the platform gathers and transfers the data into controllable factors for productivity analysis and real-time production tracking.

The Top 3 Benefits of Digitalizing Your Factory with Allion’s Product Traceability IIoT Platform

1. Factory Automation Solution

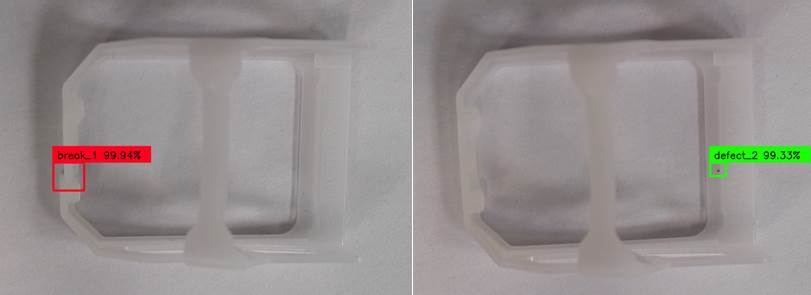

The Allion engineering team helps build the production line using vibrating plates, robotic arms, and AI visual recognition technology to automate operations and detect defects. With our IIoT platform, manufacturers can track and trace all components of a cable or connector as it moves along the production line.

2. Effective Risk Management

Sensors and vision-based monitoring systems are employed at the assembly line to oversee the manufacturing process and prevent abnormal situations. For example, cameras and live broadcast can be used to monitor site conditions at anytime to prevent accidents and safeguard confidential manufacturing information.

3. Maximum Production Efficiency

The cloud platform continuously collects key data and provides real-time review of production processes. During all stages of cable and connector manufacturing, the platform helps identify where a production problem is occurring and activates early warning systems. Based on the data-driven analysis, vendors can boost product quality and production output by making sure all production lines are operating at full capacity.

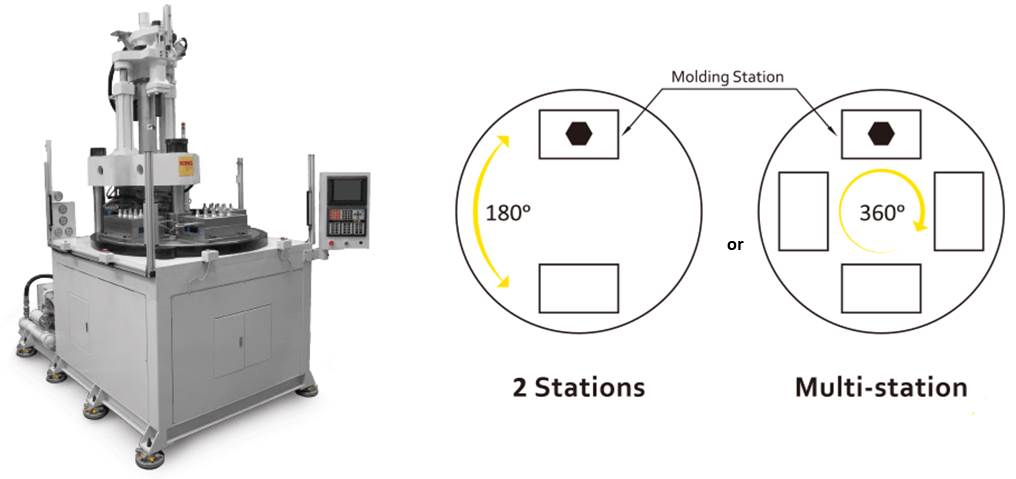

Industry Use Case 1: Injection Molding

Allion’s product traceability platform can thoroughly analyze the manufacturing environment and send notifications to alert admins of potential risks.

Operating Temperature

- Thermal cameras and temperature sensors are installed to monitor the overall temperature of the molding machine with its rotary table.

- If the operating temperature is abnormally low or high, the IIoT platform will automatically issue alerts.

- The IIoT platform records the temperature of each batch for future quality analysis

Mold Cavity Pressure

- Since the mold is already a finished product, it is not possible to attach the pressure sensor directly onto the mold itself. However, we can monitor the pressure state of the machine by comparing the current pressure value with the set through visual recognition.

- If the mold cavity pressure is abnormally low or high, the IIoT platform will automatically issue alerts.

- The IIoT platform records the pressure of each batch for future quality analysis

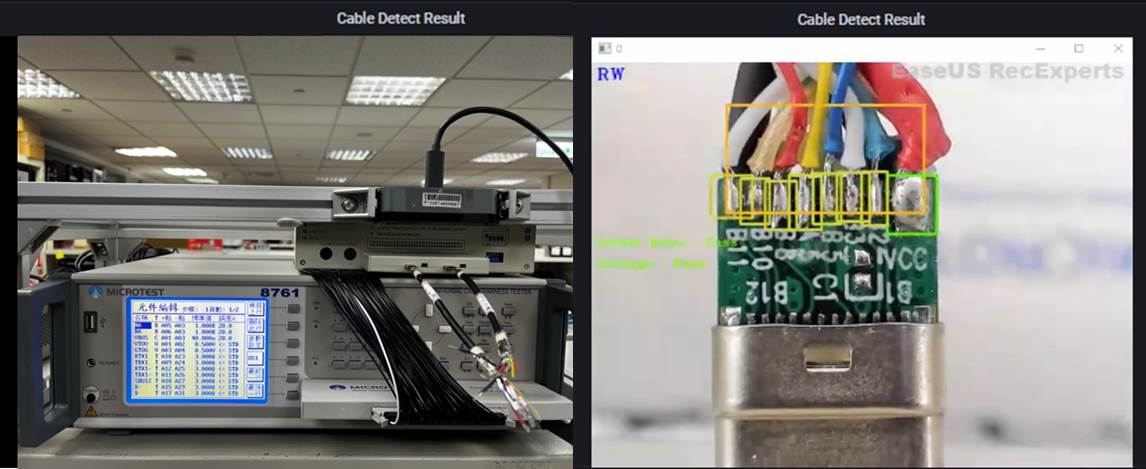

Industry Use Case 2: Cable Issue Detection

The product traceability platform can accurately detect cable issues by integrating cameras, deep learning, computer vision, and image recognition technologies.

Example: USB Type-C® Cable

- Solder ball quantity

- Solder ball defect

- Wiring sequence

- PCB circuit board identification

If you are interested in learning more about Allion’s Product Traceability IIoT Platform or other smart factory solutions, please contact us at service@allion.com